The 1990s are often remembered for their emphasis on practicality in automotive design. However, beneath the surface, many vehicles from this era were equipped with luxury features that set them apart. These understated comforts, advanced technologies, and convenient amenities were often overlooked, yet they significantly enhanced the driving experience. This article explores ten such cars that discreetly incorporated luxury elements, blending everyday usability with unexpected opulence.

mod@tech

After a period of quiet evolution, Audi is revitalizing its brand with a groundbreaking new design philosophy, signaled by the reveal of the all-electric Audi Concept C sports car. Unveiled in Milan and slated for a public appearance at the IAA in Munich, this two-seater convertible is a bold step forward, channeling the legacy of the beloved TT and the iconic R8 into a single, minimalist electric halo car.

The production version of the Concept C, expected to launch in 2027, promises to reshape Audi’s identity and capture the hearts of sports car enthusiasts. It represents a “TT moment 2.0,” a blend of clear design and emotional performance that signals a new electric era for the brand.

The Audi Concept C was led by Massimo Frascella, Audi’s Chief Creative Officer since June 2024. Before joining Audi, Frascella was the Head of Design at Jaguar Land Rover, where he was credited with shaping the current Range Rover design language.

The birth of “Radical Simplicity”

The Concept C is the first full expression of Audi’s new “radical simplicity” design language. Overseen by Chief Creative Officer Massimo Frascella, who also worked on the modern Land Rover Defender, the new aesthetic is defined by uncluttered surfaces and purposeful lines. Key design elements include:

- Vertical frame grille: Inspired by the legendary 1936 Auto Union Type C racer, a new upright vertical frame now defines the front end, giving the Concept C a distinct and modern face.

- Monolithic body: The overall silhouette is characterized by broad, muscular surfaces punctuated by a single, sharp character line. This gives the car a solid, anchored look, amplified by the cab-back proportions made possible by its central-battery layout.

- Quad-element lighting: A new four-element light signature, seen in both the headlights and taillights, creates a new visual identity for the Audi brand that will appear on future models.

- Retractable hardtop: In a first for an Audi roadster, the Concept C features an electrically retractable hardtop with two folding panels. This offers the best of both worlds: the security of a coupe with the freedom of a convertible.

A refined and distraction-free interior

Audi’s shift to simplicity extends to the cabin, which offers a stark departure from the multi-screen interiors of many current models. The Concept C embraces a “shy tech” approach, with a focus on high-quality materials and tactile feedback.

- Foldable screen: The 10.4-inch center infotainment display folds away into the dashboard when not in use, creating a minimalist and distraction-free environment.

- Tactile controls: Anodized aluminum switches and controls provide satisfying, mechanical feedback, a clear response to complaints about the capacitive touch controls found on other Volkswagen Group products.

- Sustainable materials: The interior features wool and recycled textiles instead of leather and plastic, signaling Audi’s commitment to sustainable luxury.

Performance and platform details

While specific performance figures for the Concept C are not yet available, we know a few crucial details about its powertrain and platform:

- All-electric: The production version of the Concept C will be electric-only, built on the same 800V architecture as the upcoming electric Porsche 718 (Boxster and Cayman).

- Powertrain options: Buyers will be able to choose between a single-motor, rear-wheel-drive setup or a dual-motor, all-wheel-drive system.

- Targeted range: With the shared Porsche architecture, the Concept C is likely to offer over 300 miles of range.

Production timeline and positioning

The production version of the Concept C is scheduled to arrive in 2027, with sales limited to the “low five-digit numbers” globally. Its price point is expected to land between the discontinued TT and the R8, likely in the six-figure range, offering a new entry into Audi’s performance car lineup.

This car is more than just a replacement for the TT; it is a statement of intent. As Audi streamlines its portfolio and shifts its focus, the Concept C proves that the brand’s spirit of high-performance and innovative design is ready for its electric future.

Audi Concept C Photo Gallery:

The post Audi reveals Concept C electric sports car to replace TT and R8 appeared first on The Online Automotive Marketplace.

The automotive world is buzzing, and the noise is deafening. Toyota has officially pulled the wraps off the V8-powered GR Supra that will storm the track in the 2026 Australian Supercars Championship. It’s the moment purists have been waiting for: a factory-built V8 Supra, backed by Toyota’s Gazoo Racing division, returning the legendary nameplate to its muscle-car roots.

A V8 Supra: The dream is real (for the racetrack)

For years, the idea of a V8-powered Supra has been the stuff of forums and engine-swap fantasies. Toyota is now making that fantasy a reality, though with a crucial catch: this is a purpose-built race car, not a street-legal version for the public. The Supercars-spec Supra will feature a 5.2-liter quad-cam V8, based on the high-revving 2UR-GSE engine found in Lexus performance vehicles like the LC 500.

Enthusiasts got their first thrilling taste of the engine’s sound in August 2025 via a teaser audio clip, with one Toyota executive calling the roar “absolutely spine-tingling”. The full prototype was unveiled in Sydney in September 2025, just ahead of its public debut at the Bathurst 1000 in October. Listen to the new Toyota Supra Supercar’s V8 engine roar at this link.

What this means for the Supercars Championship

Toyota’s entry into the Australian Supercars Championship in 2026 marks a historic return to the series and a new rivalry. For the first time in nearly two decades, the championship will feature three manufacturers, sparking new excitement and competition. The V8 Supra will go head-to-head with the American muscle of the Ford Mustang and Chevrolet Camaro, bringing a fresh, high-performance dynamic to the track.

The Supra’s new V8 engine boasts a racing pedigree, and Toyota has committed to a multi-year program to ensure the Supra is competitive from the start. The car will be fielded by top-tier teams, with Walkinshaw Andretti United and Brad Jones Racing already confirmed to run cars.

The end of one era, the start of another

The reveal of the V8 race car is bittersweet news for some fans. It coincides with the end of the current fifth-generation (A90) Supra’s production run, which is scheduled to conclude in 2026. The outgoing model, developed in partnership with BMW, is being given a proper send-off with a “Final Edition” model that features performance upgrades.

However, Toyota has reassured fans that a sixth-generation Supra is already in the works, promising to shorten the gap between models. This time, development will be done entirely in-house by Toyota’s Gazoo Racing division, likely featuring a new hybrid powertrain.

Toyota bid farewell to the A90 GR Supra with special Final Edition models that are expected to fetch big money. Despite the closing out of a generation, Toyota says the Supra nameplate is here to stay.

The post V8 Supra is Real: Toyota Unveils 600HP Racecar for 2026 Supercars Championship appeared first on The Online Automotive Marketplace.

Lawmakers in California rejected “Leno’s Law,” otherwise known as Senate Bill 712, during a hearing on Friday, August 29th. The bill, which had bipartisan support in the Senate and was backed by Jay Leno and the SEMA organization, would have exempted classic cars older than 35 years from the state’s biennial smog checks. The Assembly Appropriations Committee’s decision effectively killed the bill, despite its appeal to classic car enthusiasts. The law was seen as a way to protect and celebrate California’s car culture.

The bill was not passed due to concerns from environmental groups, public health organizations, and state regulators regarding potential increased smog, potential financial costs to the state, and reduced revenue from smog checks and fees. The rejection means owners of vehicles from 1976 and newer must continue to endure California’s biennial smog testing requirements, a process many find challenging and expensive for older cars. The sentiment is that these infrequently driven hobby cars should not be subject to the same stringent rules as daily drivers.

Major supporters of Leno’s Law included its sponsor Senator Shannon Grove, comedian and car enthusiast Jay Leno, the Specialty Equipment Market Association (SEMA), and various California car clubs. A host of car enthusiasts, including clubs dedicated to lowriders, hot rods, and other American classics, voiced their support. They championed the preservation of these vehicles as “rolling pieces of history”.

Many California classic car collectors and enthusiasts, along with the bill’s sponsor Senator Shannon Grove, have expressed deep disappointment that the state legislature failed to prioritize the classic car community. The bill was viewed as a step toward preserving California’s automotive heritage. Some social media comments from enthusiasts suggest a feeling that their hobby is not respected by lawmakers. Many feel the government is out of touch with the reality of maintaining and driving classic cars

Why Leno’s Law Was Rejected

After passing the Senate, Senate Bill 712 was sent to the Assembly Appropriations Committee for further review. The bill had bipartisan support in the Senate but failed to gain enough traction in the Assembly committee. The committee ultimately thwarted the bill, bringing its progress to a halt.

Public health groups, air districts, and environmental organizations opposed the bill, arguing it would increase smog and negatively impact air quality, particularly in low-income communities with high asthma rates. State regulators, including the Bureau of Automotive Repair and the Department of Motor Vehicles, warned that the bill could cost them hundreds of thousands of dollars annually by reducing revenue from smog checks and vehicle license fees. Claims also state that the passing of Leno’s Law could have costed the California Air Resources Board $1.2 million to hire new staff to collect updated data for air quality models and to revise California’s federally required pollution-reduction plans.

Assembly member Buffy Wicks of Oakland, in her introductory remarks at the start of Friday’s hearing, said the state needed to rein in costs.

“Obviously, we have an enormous amount of budget constraints still,” Wicks said. “We have to ensure that we are serving our most vulnerable folks in our communities and making sure that we are doing everything we can to put our best foot forward for a strong social safety net.”

The rejection also reflects a broader political stance in California, where the state has a long history of strict air quality regulations and a commitment to reducing emissions.

What “Leno’s Law” Would Have Done

Leno’s Law, if passed, would have created a rolling exemption, meaning any vehicle 35 years or older could be exempt from smog checks, rather than the current fixed-year cutoff. Under current law, only cars manufactured before 1976 are exempt from smog checks.

The law would have exempted classic cars from passing a smog check when a vehicle was sold and it would have waived the biennial (every two years) smog checks required for most vehicles, provided that the owners had historical license plates and collector insurance

Jay Leno testified that the current smog check requirements are a significant barrier for owners of classic cars manufactured before modern emissions standards were in place. With a modern car, it’s “plug in, get your money – boom – get out. It’s very quick to get a smog check with a modern car,” Leno said. “It’s not impossible in an older car, but it’s tricky. It takes time and often causes charges four, five, six times more than a regular car.” Leno also mentioned that many classic car owners struggle to even find a shop with the equipment needed to test them.

Senator Shannon Grove said she was “deeply disappointed that once again, the California state Legislature did not prioritize California’s classic car culture and the enthusiasts who were relying on this measure to pass.”

“Sadly, today California said ‘no’ to helping preserve these rolling pieces of history and let down classic car clubs across the state from lowriders, to hot rods and every American classic in between,” she said in a closing statement.

The post Leno’s Law is Dead: California Kills Classic Car Smog Exemption Bill appeared first on The Online Automotive Marketplace.

This is a good time to be a Ram truck enthusiast. A few months ago, Ram promised the 5.7-liter Hemi V8 would be returning to the 1500 lineup for the 2026 model year. More recently, Ram announced its Hemi-powered half-tons are now on their ways to dealerships. And those who want more sound of the high-performance Ram 1500 RHO now have two new MagnaFlow exhaust options, thanks to the Direct Connection Affiliated Accessories program.

When the Ram 1500 TRX went extinct, the Hurricane twin-turbo straight-six-powered RHO took its place as Ram’s apex predator. Although the RHO produces 540 horsepower and 521 lb-ft of torque, it’s much less potent than its 702-horsepower predecessor, plus it can’t match the sound of a big V8 (a lesson second-generation Ford F-150 Raptor fans learned). To help fill in some of that sonic gap, Ram is offering two MagnaFlow cat-back exhaust systems through the Mopar eStore or your local dealership.

The $2,089 SPEQ Series and $3,099 xMOD Series setups have the same basic hardware. Both feature full stainless steel construction, three-inch mandrel-bent tubing, MagnaFlow mid-pipe chamber with the company’s No Drone Technology (aka passive noise cancellation), Tru-X X-pipe, pair of five-inch black chrome tips, and two years of warranty coverage.

What separates the xMOD system from the SPEQ package is the level of customization and the sound it produces. The xMOD allows buyers to mix and match different components. There are three different exhaust valve modules: Street, Speq, and Comp, in order of increasing loudness. The standard mid-pipe module is integrated with the exhaust valves, but the next level up has a valve-delete design that keeps them open for more sound. Whereas the SPEQ system sounds balanced during normal driving and more vocal under acceleration, the xMOD has “six unique exhaust sound combinations, ranging from sporty to pissed off,” according to Stellantis.

There may be no replacement for displacement but, as the third-generation Ford F-150 Raptor showed me, an exhaust can make a difference. The 2017 Raptor I tested had power but no vocal presence; the 2021 model I reviewed for The ClassicCars.com Journal (equipped with an X-pipe and a “trombone loop”) made a much more satisfying sound. To hear the Ram 1500 RHO’s Hurricane blowing through one of the new MagnaFlow systems, turn up your speakers while you watch the video below.

Collector Car Network Media spotted something truly special during Monterey Car Week: a BMW M1 Procar, one of only 54 built for the legendary 1979-1980 one-make racing series. In this video, we take you through its history, from BMW Motorsport’s decision to create its first M car to the iconic Procar battles featuring Formula 1 stars such as Niki Lauda and Nelson Piquet. This particular example, delivered new to Porsche sales and motorsports icon Vasek Polak and never raced, is a time capsule of late-1970s engineering, and features a Giugiaro design, a spartan race car cockpit, and a 470-horsepower M88 straight-6capable of nearly 190 mph. In the race to buy this piece of automotive history, one bidder outran everyone else with a winning bid of $1.6 million.

This video is sponsored by Borro. For the trusted source in liquidity when you need it most, call Borro today at (720) 458-6788 or learn more at borro.com.

Subscribe to the CCN Media YouTube channel for more Monterey Car Week 2025 content.

Today’s AutoHunter Spotlight is a 1968 Chevrolet Camaro located in Oregon City, Oregon. The auction ends Friday, September 5, 2025, at 12:00 p.m. PDT.

I am often asked by people interested in buying their first collector car about what a good choice would be. If they want to buy an American sporting car, I always have the same answer: Camaro or Mustang.

The reason is simple. Both the Camaro and the Mustang are fun to drive, great to look at, and instantly recognizable by non-car people as the true collector car icons they are. In addition, both the Camaro and the Mustang have some of the best support for parts and service. At heart they are very simple cars to service and repair. They can be great cars to own for someone who wants to learn about car repair and deepen their bond as an owner.

Another benefit is that there is basically a Camaro or Mustang to suit just about every budget, from inexpensive six-cylinder cars to super-rare-optioned ones. No matter how much money you have to spend, there is likely a Camaro or a Mustang that fits the bill.

Of the two cars, I honestly prefer the Camaro. Not only is it less common, but there also is something just a bit more special about the Camaro for me. Maybe it was the timeless styling, or perhaps it was the time spent riding in and driving my high school best friend’s 1968 model and the adventures we had with Ozzy on the stereo and both of us getting up to various antics. Whatever the reason, the Camaro (especially the 1967-69 models) holds a special place in my heart.

The 1968 Chevrolet Camaro featured as today’s AutoHunter Spotlight is so close to my high school friend Jody’s car that, if you had swapped this one out for his, we might not have noticed.

The seller describes this second-year 1968 Camaro as powered by a 350ci V8 mated to a two-speed automatic transmission. Finished in red over a black vinyl interior, this classic is offered with a clear title.

The exterior of this Camaro looks to be in good shape. It was originally Butternut Yellow (in my opinion a boring color for these cars) and was repainted in red with a black accent stripe on the nose. The seller states this Camaro underwent a restoration, which I am guessing is when the color was changed. It looks like the work was well done, as the exterior is quite nice.

The car rides on Chevrolet 15-inch Rally wheels clad with staggered 215/40 front and 255/60 rear Tornel radial tires.

The interior was originally equipped with a front bench seat and center arm rest, which is on the rarer side for Camaros. These are covered with correct-pattern black vinyl. Other interior changes include an aftermarket Boss Audio Systems stereo and dash-mounted aftermarket gauges for oil pressure and water temperature. Overall, the interior looks to be in excellent condition. While purists might not like the seat change, I would never want a bench seat in a Camaro – not only do they look weird in a sporting car, but they are also less comfortable.

Under the hood of this Camaro is a 350ci V8 that has a chrome dress-up kit and the spectacular Holley Sniper EFI system. Forget about carbs—this system is better and more reliable in every way and offers the unique combination of increased performance and reliability. It also features an aluminum radiator with electric fans.

There are other mechanical changes as well, including tubular A-arms with poly bushings, power front disc brakes, and a dual exhaust system.

The overall condition of the car and the changes made to it make this a classic first-generation Camaro you can drive every day, take on tours, and show off with pride at a local car show.

If you are in the market for either a first classic car or simply another classic car to drive and enjoy, take a hard look at this tastefully modified 1968 Chevrolet Camaro as a potential choice. If you are interested, though, you have bid on it. The auction for this ends Friday, September 5, 2025, at 12:00 p.m. PDT.

Visit the AutoHunter listing for more information and a photo gallery

For someone born in the early 1980s, this 1933 Chevrolet Series O 1.5-ton flatbed is an absolute antique. It is the kind of vehicle you would expect to see in a hometown parade or giving hayrides at a pumpkin farm in the fall. The tall and narrow radiator and headlights-on-a-crossbar are unmistakable early 1930s visual cues, and the combined width of the dual rear wheels are eclipsed by the mag wheels on the rear of a 1970s street machine. It is difficult to come to terms with the age of this vehicle when you were born just in time for 5.0-liter Mustangs, Jeep CJ-8 Scramblers, and the DeLorean. However, I think I have a way to explain the age of this truck in a way that’ll make perfect sense.

Meet my grandfather, Ken. Ken was born in Iowa in late 1918. This truck would’ve been brand-new when he was fifteen years old, working farm jobs near Des Moines. There’s a solid chance that he drove a truck like this back in the day. There’s a certain chance that he rode on one or in one as he busted his backside to make sure there was food on the table during the height of the Great Depression. You can picture him working with a couple other young men his age, chucking bales of hay onto the bed in a field somewhere. And keep in mind, just because automobiles had been around for a while at this point didn’t mean that horses and buggies were a thing of the past yet. This was just another workhorse… except it didn’t need any hay.

Take note of the license plate on the truck: 1956. A couple of decades on, Ken was in the middle of his military career. He joined the United States Army Air Corps as a lieutenant just in time for World War II, had married a fiery woman from Oklahoma and was starting a family. By the mid-1950s he had made the transition to the Air Force and was leading combat communications units, a role that he would continue with until his retirement as a full-bird Colonel in the early 1970s. In the Fifties, the Chevy was another used truck on the scene. No flashy chrome, no two-tone paint, no V8 moving it along. It was a relic, a throwback, or any period-correct slang used to describe how out-of-date it was. When Ken retired, trucks like this Chevrolet, if they were still in service at all, were working close to the farms that muscle cars and station wagons roared by.

That photograph was taken in 1988, when I was five. A truck like our featured Chevrolet was an antique. Most of the ones that were still in one piece were yard art items or museum pieces. A working flatbed truck of this vintage was the odd man out. There were more comfortable, more powerful options available that were still simple to maintain and operate. There were competent pickup trucks that could do the work and provided creature comforts like air conditioning and automatic transmissions. Ken certainly had moved on with the times. Deep into his retirement, he had just traded a 1984 Chrysler E-Class for a 1989 Chrysler New Yorker, while his trusty 1978 Ford F-250 Camper Special was parked next to the house, ready for the next mission.

It’s 2025. This Chevrolet is a few years short of a century of service, still running, still more-or-less unchanged from the day somebody handed over a few hundred hard-earned dollars for what may have been their first powered vehicle. Ken passed on in 2007, a month or two after his wife. His grandchildren are enjoying adulthood, from my college-aged cousins to myself, who is past the mid-way mark and is getting close to that hill everyone talks about. Decades of history and major world events have passed by since this truck was delivered to the dealership that sold it. The world went from horse-drawn implements to the Atomic Age and beyond any wild dream a kid from 1933 would’ve had. How would you explain things like supersonic aircraft, space exploration and the internet to a farm kid from Iowa? He’s just floored that a new flatbed Chevrolet has pulled into the farm, ready for its first day of work.

In 2025. My joints crack, my bones ache, I still have many miles to go myself, and I’m just floored that this truck is still in one piece, weathered but original, and is still ready to work.

The post This 1933 Chevrolet Flatbed Has Seen Many Lifetimes’ Worth Of History appeared first on The Online Automotive Marketplace.

When it comes to European-style grand touring cars, the U.S. hasn’t produced many. The most prominent one that comes to my mind is Studebaker’s superb 1962-’64 Avanti and its successors. The Studebaker Hawk series, to include the Silver Hawk, Golden Hawk, GT Hawk, etc., also qualifies, in my opinion. Nash-Healey doesn’t—it’s more a sports car. Buick Reatta and Cadillac Allanté, on the other hand, are fine examples of grand tourers, and great cars. Other than a few efforts by a handful of the smallest Independents, like Cunningham, that’s about it.

Even rarer are U.S.-made Euro-style supercars. The list of American supercars produced prior to the 1990s includes…what? Shelby Cobra? I don’t feel it qualifies, because it’s basically a hot rod, an AC sports car with a V8 stuffed under the hood. The 1953-2000’s Corvettes are great sports cars but they fall short of supercar status.

However, at least two American cars from the 1946-1989 era qualify as supercars. The first supercar title goes to the fabulous Ford GT40, produced from 1964 to 1969. Number Two? That would be American Motors’ AMX/3.

Before you head over here with pitchforks and torches, let me explain my reasoning. The AMX/3 has all the requisite attributes of a supercar: incredibly sexy styling, exotic mid-engine chassis, and a potent V8 engine for extraordinary performance. Sure, it’s a little difficult to call it an American car since many of its mechanical bits were designed in Europe, including its chassis and OTO Melara transmission. But the same might be said of the GT40.

I think some background on AMX/3 might help convince you. In 1966, AMC investor (and later chairman) Roy Evans began pushing a stronger performance image for the company. He greenlighted the new Javelin and insisted AMC’s two-seat “AMX” concept also go into production. Soon, Evans and AMC Chairman Roy D. Chapin Jr. began to consider outdoing the Corvette by fielding a mid-engine supercar. Designer Bob Nixon created a full-size mockup dubbed AMC/2. Its low, sleek, over-the-top styling was an immediate hit with audiences. Then Styling VP Dick Teague came up with a design thought to be even more appealing, and it was chosen.

Chassis development began at Bizzarrini in Italy, with assistance by American Motors engineers. The body/chassis was semi-monocoque, with a body height of 43.5 inches. An AMC 390-cube V8 was mounted behind the cockpit, hooked up to a ZF transaxle on the first car, a Melara unit on subsequent cars. A 3.54:1-axle ratio provided blistering acceleration of 0-60 in 6.1 seconds and a 160-mph top speed. For production, AMC considered Karmann, Coggiolla, or Bizzarrini but, in the end, chose Autofficina Salvatore Diomante.

AMX/3’s U.S. debut at the New York Auto Show in April 1970 drew rave reviews. However, AMC management was beginning to realize its beautiful car couldn’t be put into large-scale production. Costs were the problem. An original goal of selling 5,000 cars a year proved unrealistic. The next goal, 1,000 cars annually, would have meant a minimum selling price of $20,000 per, and even that might be unprofitable. Chapin told me they finally decided $12,000 was the most they could hope to charge; roughly double that of Corvette. He decided building cars on which AMC would lose $8,000 each wasn’t a good idea.

Officially, only six AMC/3s were built, but several people later announced “discovery” of more examples, some reportedly constructed from leftover parts.

Whatever the actual number is, these rare cars are extremely expensive and worth every penny. I knew and liked Roy Chapin, but his decision was wrong; if AMC had offered even just 25 AMX/3s for sale per year, their reputation for performance and innovation would have soared. But as they say, hindsight is always 20/20.

Lead Photo: In a Javelin Racing Team jacket, racing legend Mark Donohue appears with the third of the six AMX/3s at Michigan International Speedway in 1970.

The post Independent Thinking: America’s Second Supercar? appeared first on The Online Automotive Marketplace.

We can look at brochures and dealer books and learn what was available for a particular model year, but those won’t provide a complete picture of things as they evolved over the model year. Our Pick of the Day is one of those cars that you won’t find in most literature; that’s because it was a promotional package created by a marketing department early in the calendar year. This 1967 Plymouth Belvedere Silver Special two-door hardtop is listed on ClassicCars.com by a dealer in Elkhart, Indiana.

The Silver Special name has been used by Plymouth since 1958. It was first applied to a mid-year promotion for Plaza two- and four-door sedans to kick sales up a notch. Equipped with whitewall tires, deluxe wheel covers, fender ornaments, and anodized aluminum “Sportone” side trim with a matching metallic silver roof, the Silver Special was a nicely dressed version of Plymouth’s cheapest model.

The Silver Special was revived for 1966, though now applied to the Fury II four-door sedan. The Silver Special was available in five colors (white, light blue, light metallic blue, dark metallic blue, and silver) and included these extras as standard equipment: whitewalls, deluxe upper door moldings, special wheel covers, and a blue vinyl interior.

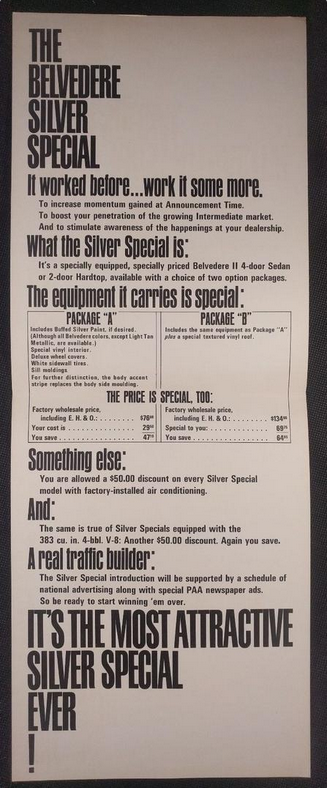

The Silver Special reappeared for 1967, now based on the Belvedere II two-door hardtop and four-door sedan—again, a specially equipped, specially priced mid-range Plymouth. “It worked before…work it some more,” said the special brochure created for this promotion. There were two packages available: Package A included Buffed Silver paint or any other regular color save Light Tan metallic, a special silver and black vinyl interior, deluxe wheel covers, whitewall tires, and sill moldings; Package B added a special textured vinyl top in a silvery charcoal color. If air conditioning or a 383 four-barrel was ordered, a $50 discount for each was implemented.

You may not have heard of the Silver Special because, other than the special interior, there’s not much that makes it stand out from your typical Belvedere II. Additionally, the Belvedere II was not a performance model, so it’s often modified by enthusiasts, sometimes losing its identity. According to the seller, this Gold metallic 1967 Belvedere Silver Special has what’s “believed to be 21,500 original miles,” adding that it is powered by a “well-built, fuel-injected 360 cubic-inch V8 backed by its 3-speed automatic transmission” that “has been nicely upgraded with Hooker long tube headers, aluminum heads, Edelbrock mild-rise EFI intake manifold, Edelbrock electronic fuel-injection, and aluminum radiator with electric puller fan.” Other features include power front disc brakes, an aftermarket Optimus AM/FM stereo with a cassette player, and more.

Sure, there’s nothing on the outside to show that this Plymouth is more interesting than any other Belvedere out there, but the silver lining is in the cabin. For $34,995, is this Mopar gold?

Click here to view this Pick of the Day on ClassicCars.com