The 1990s witnessed a surge in automotive innovation, with manufacturers introducing models that combined performance, style, and technology. However, in some instances, the base versions of these vehicles offered a more engaging and reliable driving experience than their upgraded counterparts. Factors such as lighter weight, enhanced reliability, and a purer driving feel contributed to the base models’ appeal. This phenomenon highlights that, in the realm of automotive design, more isn’t always better. Let’s delve into 15 such cars from the 90s where the base model outshone its upgrade.

mod@tech

The 1980s marked a transformative period in the automotive industry, as manufacturers sought to blend performance, technology, and versatility to appeal to a diverse consumer base. This era witnessed the emergence of vehicles that combined features from various segments, resulting in unique and sometimes unconventional designs. Technological advancements and shifting consumer preferences drove automakers to experiment with multipurpose vehicles, leading to some memorable and ambitious models. (en.wikipedia.org)

Between the 1970s and 1990s, car dealerships offered a range of unique dealer-installed options that reflected the automotive culture and consumer trends of the era. These features, often designed to enhance performance, comfort, or style, sometimes led to unexpected outcomes. Exploring these options provides insight into the innovative and sometimes questionable choices made by both manufacturers and consumers during this period.

Three years ago, I spent a week driving the all-electric 2022 Hyundai Ioniq 5. It was a daring retro-futuristic design wrapped around an airy, spacious cabin and propelled by a powerful pair of electric motors. To make a long story short, I loved it. Would the thoroughly updated 2025 model be just as wonderful? There was only one way to find out.

Prices for the 2025 Ioniq 5 start at $42,600 for the entry-level SE Standard Range model and top out at $54,300 for the Limited with rear-wheel drive. My dual-motor Limited test vehicle came standard with HTRAC all-wheel drive, a V-shaped LED accent bar, 20-inch wheels, a large fixed glass roof panel with a retractable shade, a head-up display, heated and ventilated front seats, Bose audio, a 12.3-inch digital instrument cluster, a 12.3-inch infotainment touchscreen, and more. Adding carpeted floor mats and the $1,000 Gravity Gold Matte paint raised the total price to $60,785.

As part of the Ioniq 5’s mid-cycle refresh, Hyundai made comprehensive visual, technological, and powertrain changes. The immediately recognizable 8-bit exterior was not only updated with new bumpers, a rear wiper and washer, and fresh paint colors, but with structural enhancements to the doors, B-pillars, and body as well. Luckily, none of those alterations were too extreme – the Ioniq 5 is still as quirky and distinctive as before.

The cabin comes with new features that make it more convenient. In properly equipped models such as my Limited AWD test vehicle, the sliding center console now has a wireless phone charging pad as well as physical controls for the heated and ventilated front seats and the redesigned heated steering wheel. Too bad Hyundai didn’t use buttons and switches for the new HVAC controls, which are touch-sensitive and difficult to use on the fly.

Two of the most significant updates to the Ioniq 5 are the switch to higher-capacity lithium-ion battery packs and the standard NACS (North American Charging Standard) charging port, which enables the Ioniq 5 to use Tesla Supercharger stations. The Limited AWD has a 74-kW front and a 165-kW rear electric motor, which produce a total of 320 horsepower and 446 lb-ft of torque. According to the EPA, it’s capable of returning 98 MPGe combined. On a full charge, the Limited AWD can cover 269 miles, a slight increase from its previous range of 260. When connected to 250+kW power, the battery goes from 10 to 80 percent full in 20 minutes. Unfortunately, the Electrify America station closest to my house was much slower, taking the battery from 10 to 80 percent in 53 minutes. Let’s just say I spent a lot of time browsing the nearby Walmart’s Hot Wheels and Lego aisles that afternoon.

On the road, the Ioniq 5’s cabin was just as soothing and airy as it was in the 2022 model. Although the suspension had a touch of firmness, it didn’t detract from the serene driving experience. When I needed to pick up the pace, the dual motors carried me forward at a brisk pace. I quickly realized that when Hyundai developed the new Ioniq 5, it didn’t “fix” something that wasn’t broken in the first place.

To learn more about the 2025 Hyundai Ioniq 5 Limited AWD, check out my review video below.

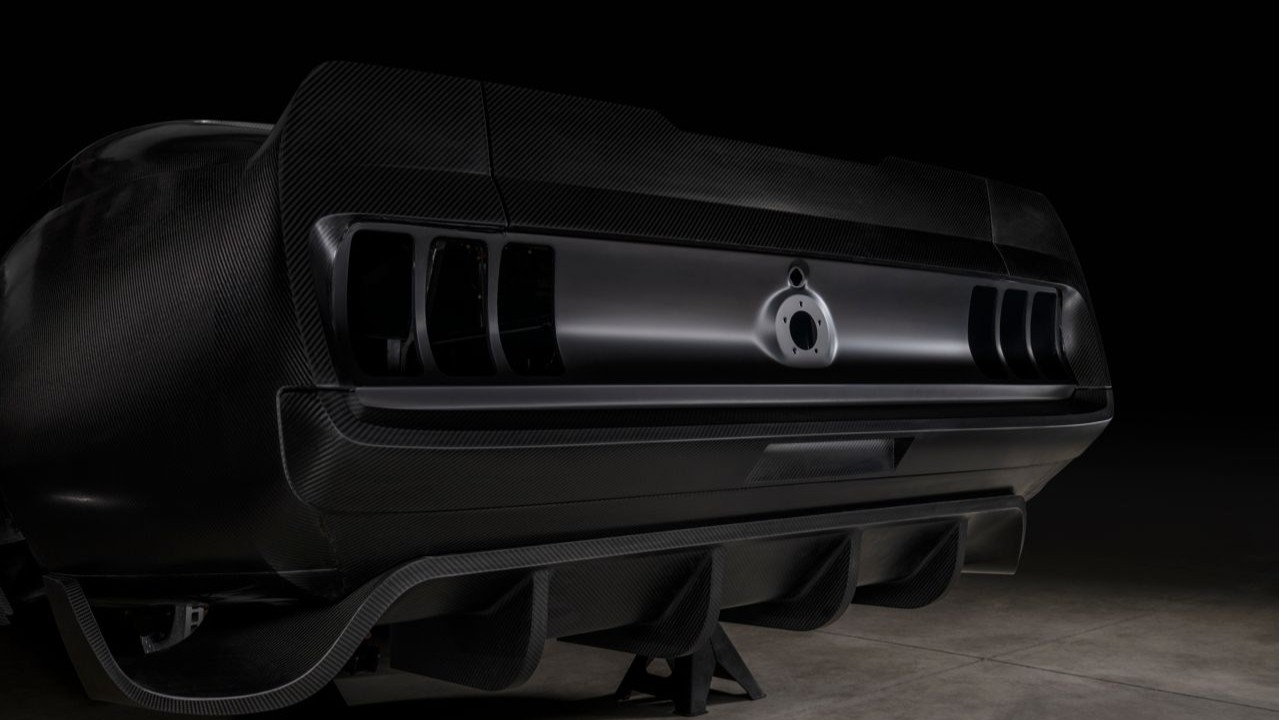

Are you a Mustang fan but feel you don’t measure up running against those widebody Dodge Challengers and Chargers? Do you feel that Ford fans have had sand kicked in their faces for too long, yet the Mustang GTD is sold out? You now have another widebody solution (and it doesn’t require you to send in a stamp to Charles Atlas) as Trick Rides has previewed its first widebody Mustang—not only is it a ’69, but it also is made completely out of carbon fiber.

Trick Rides has reimagined the 1969 Mustang “SportsRoof” engineered entirely in CAD with advanced 3D-scanning technology for “aerospace-level precision.” This interpretation of Ford’s pony car features “advanced aerodynamics” and panel fitment that would make a Lexus fan blush. Of course, carbon fiber weighs less, too.

This body will be the basis of “Scorched,” a custom 1969 Mustang created in collaboration with TMI Products. The latter company contributes with a custom interior that includes all-new high-back seating, German square-weave carpeting, custom-bade door panels, console, and Alcantara headliner—all made and installed in America!

“Our latest creation, ‘Scorched,’ represents a new era in muscle car engineering and design,” says Jason Engel, founder of Trick Rides. “Our goal was to push the boundaries of what a resto-mod could be by adding modern twists to a timeless classic. The result showcases what is possible when modern engineering meets iconic heritage.”

If you’re interested in buying your own Scorched, you can choose from several engine options: a VMP-supercharged 5.0-liter Coyote V8, 429 cubic-inch Kaase “Boss Nine,” or Ford Performance 427 cubic-inch V8, all featuring a custom exhaust system with Stainless Works headers and MagnaFlow mufflers. A TREMEC T-56 six-speed manual will make your left leg and right arm larger.

The chassis comes from the Roadster Shop and boasts a Fox coilover independent front suspension, parallel four-link rear, and oversized sway bars for increased stability. Three-piece Forgeline wheels are wrapped in Continental ExtremeContact Force tires, while brakes are custom six-piston Baer Brakes.

The first completed vehicle will make its official debut in the TMI booth (#24477) in Central Hall at the SEMA Show this November in Las Vegas. Yet you don’t have to wait several months to find out all about this special vehicle—simply visit the Trick Rides website to learn how you can buy one.

This 1932 Ford is a roadster built by its original owner in the 1950s from a steel-bodied original Ford Model B, according to the seller. It is powered by a 221ci flathead V8 topped by a Thickstun intake manifold and matching heads, and it is believed to have been rebuilt by Jack Roush. A ’39 three-speed manual transmission with Zephyr gears linked to a Halibrand quick-change rear end was also used. The steel body features a louvered hood, blue paintwork, a white scallop mask, chrome spreader bars, a cowl vent, and a white soft top, and the blue interior has door pockets, a four-spoke wheel, and Stewart-Warner gauges. The seller acquired the roadster in 2015, and service in 2025 included replacement of the brake slave cylinder, installation of new brake shoes, a carburetor rebuild, and fluid changes. This Ford roadster is now offered with a clean Texas title in the seller’s name.

The seller believes the car was built into a hot rod in the 1950s by its original owner. It has blue paintwork with a white scallop mask, and it features a cowl vent, a louvered hood, chrome spreader bars, and blue-dot taillights. The white soft top is removable.

The 15″ steel wheels are mounted with big-and-little Firestone Dirt Track tires, which the seller states were shaved to true. Braking is provided by four-wheel drums, and service in 2025 included replacing the slave cylinder and brake shoes. The car rides on transverse leaf springs with split wishbones front and rear and a tubular drop axle up front.

The blue interior has door pockets, a four-spoke wheel, and Stewart-Warner gauges.

The 221ci flathead V8 is topped by a Thickstun intake manifold with dual Stromberg 97s and matching heads, and it is believed to have been rebuilt by Jack Roush.

A ’39 three-speed manual transmission with Zephyr gears is linked to a Halibrand quick-change rear end.

The car is titled as a 1932 Ford using VIN B5115623.

This ’30 Ford Model A is a steel-bodied, full-fendered, five-window coupe previously owned by race car driver and artist Bob McCoy. Reportedly one of his last daily drivers, the car built using an original Model A coupe body that has 206 louvers and hand-painted Pegasus accents. Acquired by the seller in 2019 and mechanically overhauled between 2021 and 2025, it is now powered by a 302ci V8 with an Edelbrock carburetor and intake manifold that is linked to a C4 three-speed automatic transmission and a 3.50 limited-slip differential. The body is mounted on a custom-built chassis with a drop front axle, hairpin radius rods, rear ladder bars, and disc brakes up front, and inside are Stewart-Warner gauges, a Lokar shifter, an adjustable seat, and a ’40-style steering wheel on a Flaming River column. This hot rod A is now offered in with McCoy memorabilia and transferable New York registration listing the car as a 1931 Ford.

McCoy owned and reportedly used the car as his daily driver in the early 2000s, and it remained with his family through 2015. The steel-bodied coupe is reportedly an original Ford 1930 A five-window that was chopped. McCoy hand-painted the Pegasus logos on the louvered hood, and the car features a total of 206 louvers.

Following the seller’s acquisition in 2019, the car was disassembled and mechanically refreshed. Work involved powder-coating the custom-built chassis gloss black as well as installation of the drivetrain at California Dreamin’ Hot Rods. The suspension was also powder-coated and features a drop front axle, hairpin radius rods, rear ladder bars, transverse leaf springs, and disc brakes up front.

The car retains a red primered finish, and LED headlights and taillights with integrated turn signals are used.

The painted steel wheels have big-and-little Diamondback whitewalls mounted by the seller.

The seat is from Wise Guys and adjustable, and a Sony stereo has been installed along with speakers. The Lokar shifter pattern does not match the Ford automatic.

A Flaming River steering column, ’40-style steering wheel, and Stewart-Warner gauges were installed by the seller. The seller has driven all of the ~150 indicated miles.

California Dreamin’ installed the 302ci V8, which it topped by an Edelbrock intake manifold and carburetor. Sanderson headers were also fitted along with a Powermaster mini-starter, a single-wire alternator, Taylor plug wires, and Mallory ignition. An electric fuel pump and dual electric cooling fans were also used.

The C4 automatic transmission is linked for a Ford rear end with a 3.50 limited-slip differential. The fabricated exhaust system is ceramic-coated.

Signed McCoy artwork artwork and a copy of the book Circle of Impact by Lynn McCoy are included.

The car is registered as a 1931 Ford using VIN A3850461, which aligns with a 1930 model. The transferable New York registration acts as proof of ownership.

This 1932 Chevrolet BA Confederate coupe was built into a street rod under prior ownership, and it is powered by a 350ci V8 linked to a 700R4 four-speed automatic transmission and a 10-bolt rear end. The three-window, full-fendered steel body is finished in “chameleon” metal-flake paint and features rear-hinged doors with electric poppers, and the car rides on a Heidts Mustang II-style front assembly with adjustable front coilovers, four-wheel disc brakes, and Billet Specialties 17” wheels. Inside, beige vinyl upholstery is complemented by an overhead console, a Lokar shifter, a Pioneer CD head unit, power windows, and Classic Instruments gauges. This custom Chevrolet is now offered with a North Carolina title in the seller’s name.

The doors were shaved and mounted on concealed rear hinges before the car was finished in metal-flake paint that shifts between green, gold, and brown depending on the angle of lighting. Electric poppers were installed for the doors and trunk lid, and other details include a roll-down rear window, running boards, oval side mirrors, side exhaust outlets, and rectangular LED taillights. Paint chips and cracks are noted around the car and shown in detail in the gallery below.

Billet Specialties 17” wheels are wrapped in 225/65 Yokohama Avid Touring-S tires. A Heidts Mustang II-style independent front assembly with adjustable coilovers has been added along with a racing-specification manual steering box, while the live rear axle is supported by longitudinal leaf springs. Braking is handled by four-wheel discs.

The cabin features bucket seats trimmed in beige vinyl upholstery that extends to the headliner, rear bulkhead, and door panels. Color-coordinated square-weave carpets line the floors, and an overhead console houses storage compartments, courtesy lights, and controls for the power windows. Additional appointments include a Lokar shifter, a Pioneer CD head unit, and a klaxon-style horn.

The two-spoke billet steering wheel sits ahead of Classic Instruments gauges consisting of a 140-mph speedometer, an 8k-rpm tachometer, and auxiliary readouts. The six-digit odometer shows 3,600 miles, approximately 300 of which have been added under current ownership.

The 350ci V8 is equipped with a Holley carburetor, a Mallory distributor, and short-tube headers that flow into a dual exhaust system. The aluminum radiator is cooled by an electric puller fan, and a 12-gallon fuel tank has been installed.

A 700R4 four-speed automatic transmission is linked to the 10-bolt rear end.

The car is titled as a 1932 CHEV REPLICA using the North Carolina Assigned VIN NCS106130. The title carries a “RECONSTRUCTED” brand.

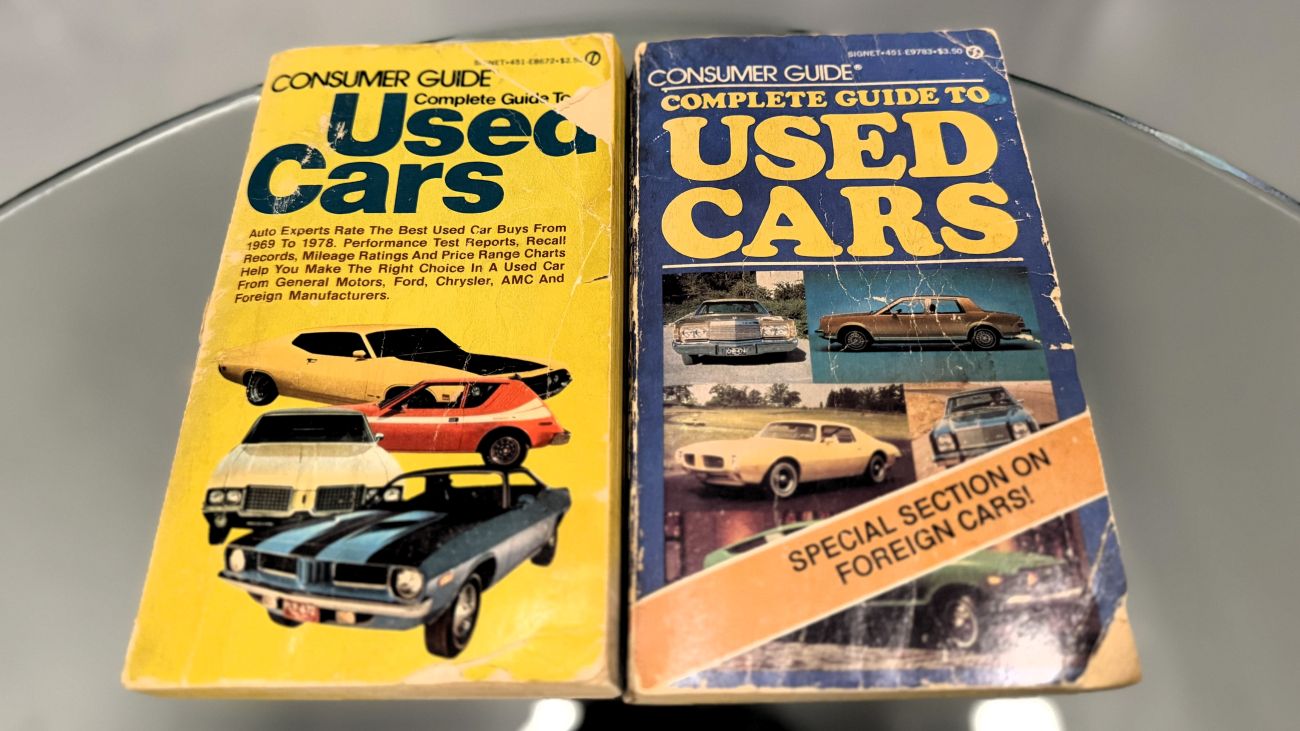

While it currently appears Consumer Guide loved the Plymouth Valiant and Dodge Dart the most among all the used cars from the 1970s, the Ford brand was preferred as a whole. Sure, Ford had its issues—especially with overstyled sedans in all classes, and being late to the downsizing party—but it seems build quality was higher and recalls were fewer.

Does that also hold true for Mercury?

Most models were shared together, so possibly. But we also know distinctions can exist depending on engines and options. Let’s take a look at Mercury, then you can compare the below ratings with those for Ford. Please note the CG rating scale of 5 being Excellent and 1 being Poor.

Mercury

“Lincoln-Mercury cars have set new standards for quiet operation and comfortable rides.”

- Bobcat: “With the smaller engine [four-cylinder versus the V6], Bobcat owners can have the power train that has the best overall repair record in the American subcompact class.” CG rating: 4

- Capri (Import): “Capri’s repair history has been precisely opposite that of the Pinto, despite identical components.” CG rating: 3-4

- Capri (Domestic): “Overall repair record for ’79 models slightly below average with standard four, dismal with V6.” CG rating: N/A

- Comet: “Dull but dependable, and a safe choice among compacts of the early ‘70s.” CG rating: 4

- Cougar: “Repair record average to slightly below average. Electrical, brake, and suspension crop up in [early cars]. The 1974 through 1976 Cougars have above average repair records. It appears the newer [1977] model is not holding up as well.” CG rating: 2

- Monterey/Marquis: “The cars have excellent service records and live up to their images of quiet and comfort … but Marquis is a leftover from an age that is about to pass.” CG rating: 2

- Monarch: “Like people, there are cars that make great first impressions, then quickly wear out their welcome. The Mercury Monarch is just such a car.” CG rating: 2

- Montego: “Overstyled, overweight mid-size car with too much thirst and too little practicality.” CG rating: 2-1

- Zephyr: “Sketchy frequency-of-repair data, but overall record is average so far with either four- or six-cylinder engine.” CG rating: 4-5

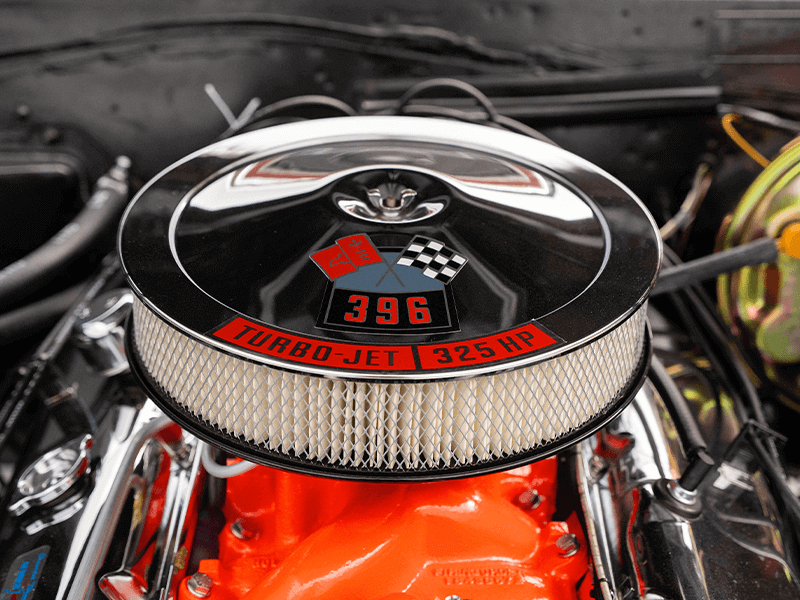

There are moments in life when history and destiny meet at the turn of a key. Picture yourself stepping into your garage on a cool autumn morning. The golden light spills across polished chrome, glinting off the unmistakable lines of a 1966 Chevrolet Chevelle SS396. You slide into the driver’s seat, wrap your hands around the wheel, and with one twist of the ignition, the 396-cubic-inch big-block V-8 comes alive. The deep rumble fills the air, not just with sound, but with soul—the kind of sound that defined Detroit’s glory days.

This is the Zero-to-Sixty Dream Giveaway, and it’s your chance to bring home one of the most legendary muscle cars ever built. This Chevelle SS396 has been restored, capturing the essence of American muscle in its purest form. Under the hood lies a 325-horsepower L35 big-block engine mated to a 4-speed Muncie manual transmission. A Positraction limited-slip differential ensures the power makes its way to the pavement, while dual exhausts deliver the throaty roar that made the SS396 an icon nearly sixty years ago. Click here to enter now!

Finished in breathtaking Aztec Bronze, this Chevelle is a bridge between past and present, a time machine back to an era when horsepower ruled the roads. From the bench seats to the flowing Coke-bottle contours, every detail reminds you why the mid-sixties were a golden chapter in the book of American performance.

The grand prize includes $16,000 to cover federal prize taxes, easing the financial worry and letting you focus entirely on the joy of ownership.

Here’s the most important part—you don’t have forever. The sweepstakes runs only through October 14, 2025, and the winner will be announced on October 28, 2025. That date is closer than you think, and once it passes, the garage door will close on your chance to own this piece of muscle-car history.

So the question is simple: will you let this opportunity slip away, or will you seize it before time runs out? The Chevelle SS396 is waiting. The key could soon be in your hand. The road ahead could be yours. But only if you enter before the deadline.

Don’t wait. Enter today.