Launched in 2003, Scion was Toyota’s bold experiment to captivate younger, trend-conscious drivers with distinctive designs and a no-haggle pricing model. Despite its innovative approach, the brand faced challenges and was discontinued in 2016. However, many of its models have experienced a resurgence in popularity, gaining a cult following and becoming symbols of automotive individuality. This article explores ten Scion vehicles that have become cooler since the brand’s demise.

mod@tech

Toyota has long been synonymous with reliability and practicality, often overshadowing its performance-oriented engineering. However, beneath this mainstream image, certain models have been crafted with features that appeal to driving enthusiasts. These vehicles offer uniquely sporty dynamics, engineering quirks, and tuning potential, showcasing Toyota’s commitment to performance. In this article, we explore ten such models that reveal Toyota’s hidden legacy in the realm of automotive excitement.

Remember when Nissan applied the Pathfinder name to a unibody crossover for 2013? It was like Nissan was watching Dodge introduce a four-door Charger and thought, “Let’s also do something that makes no sense!” So, will Nissan exhibit more common sense with the reintroduction of the Xterra for 2028?

Yup, you’re reading that right—according to Bloomberg, Nissan Americas chairman Christian Meunier has confirmed that the Xterra will be returning for 2028 and will be built at Nissan’s Canton, Mississippi plant. “The dealers are super excited about it because it’s going to be a great example of Nissan coming back,” Meunier told Bloomberg. Wasn’t the Z supposed to do that?

Nonetheless, the rumors have been around for several months already. Automotive News reported this past August that a supposed 2028 Xterra vehicle would rely on a hybrid V6 powertrain.

Car and Driver approached Nissan for a statement and received this: “We are considering the revival of the Xterra nameplate as a hybrid SUV, with a potential launch in 2028. Production is being evaluated for our Canton, Mississippi facility. The return of Xterra would represent a strategic move to strengthen our position in the mid-size off-road SUV segment.” Car and Driver adds that the Xterra has been substituted in the place of a planned EV SUV.

Nissan has already commenced with plans to release 20 new and updated models for America and its northern neighbor through the spring of 2027—now we can say at least 21 models through 2028. If you look at Nissan’s current SUV portfolio, note that it leans heavily towards crossovers, so we’re betting that the Xterra will most certainly be the “Comeback Kid” that Nissan fans are hoping for.

Lexus isn’t the only luxury automaker creating lifestyle-focused custom builds. Bentley recently partnered with Danish food and beverage brand Joe & The Juice to create a custom Bentayga with an onboard coffee shop.

Bentley says the one-off was “designed for intimate events that bring communities together” and “can serve espressos in urban and cultural settings before swiftly moving on to its next destination. It transforms the Bentayga into the world’s most luxurious coffee experience, where cutting-edge design meets the perfect brew.”

The Bentley x Joe & The Juice Bentayga’s barista uniform is Bentley Green and Joe’s Signature Pink, accented with a combination of the two companies’ logos. In the cargo area, Bentley’s Mulliner bespoke division installed a setup with green leather panels and pink details that includes a grinder, espresso machine, and fridge. The whole station can be slid out to sling coffee and espresso at community events, then retracted so the Bentayga can move on to the next gathering.

People who attended the Bentley x Joe & The Juice Bentayga’s launch event at Duke of London in late September got the first taste of its caffeinated creations, but you may get a chance to try them in the future. The partnership between the two companies will fully launch next year, and the custom Bentayga will go on “an international tour of cultural, lifestyle and design events.” Where exactly will those be? Ask someone at Bentley after they’ve had coffee.

Right now on AutoHunter, you can find this 1955 Mercury Custom Station Wagon, which is powered by a Super-Torque 292ci V8 mated to a Merc-O-Matic three-speed automatic transmission. Finished in light and dark blue over a black plaid cloth and gray vinyl interior, this six-passenger wagon is now offered by the selling dealer in Oregon with a clear title.

The body and roof are finished in light blue, while the pillars are finished in dark blue. Exterior features include chrome bumpers, hood ornament, Full-Scope wrap-around windshield, bright trim, dual side mirrors, sliding rear side windows, lift-up rear window, tailgate, and dual exhaust outlets.

A set of 15-inch steel wheels with covers and 225/75 whitewall radials get passengers and/or cargo to their destinations.

Black plaid cloth and gray vinyl cover the first-row bench and second-row split bench seats, as well as the door panels. Cabin features include manual windows, power steering, AM radio, clock, under-dash Vintage Air Mark IV air conditioning system running R-134a, lap belts, under-seat storage areas and fold-down seatbacks in the second row, and spare tire under the rear cargo area floor.

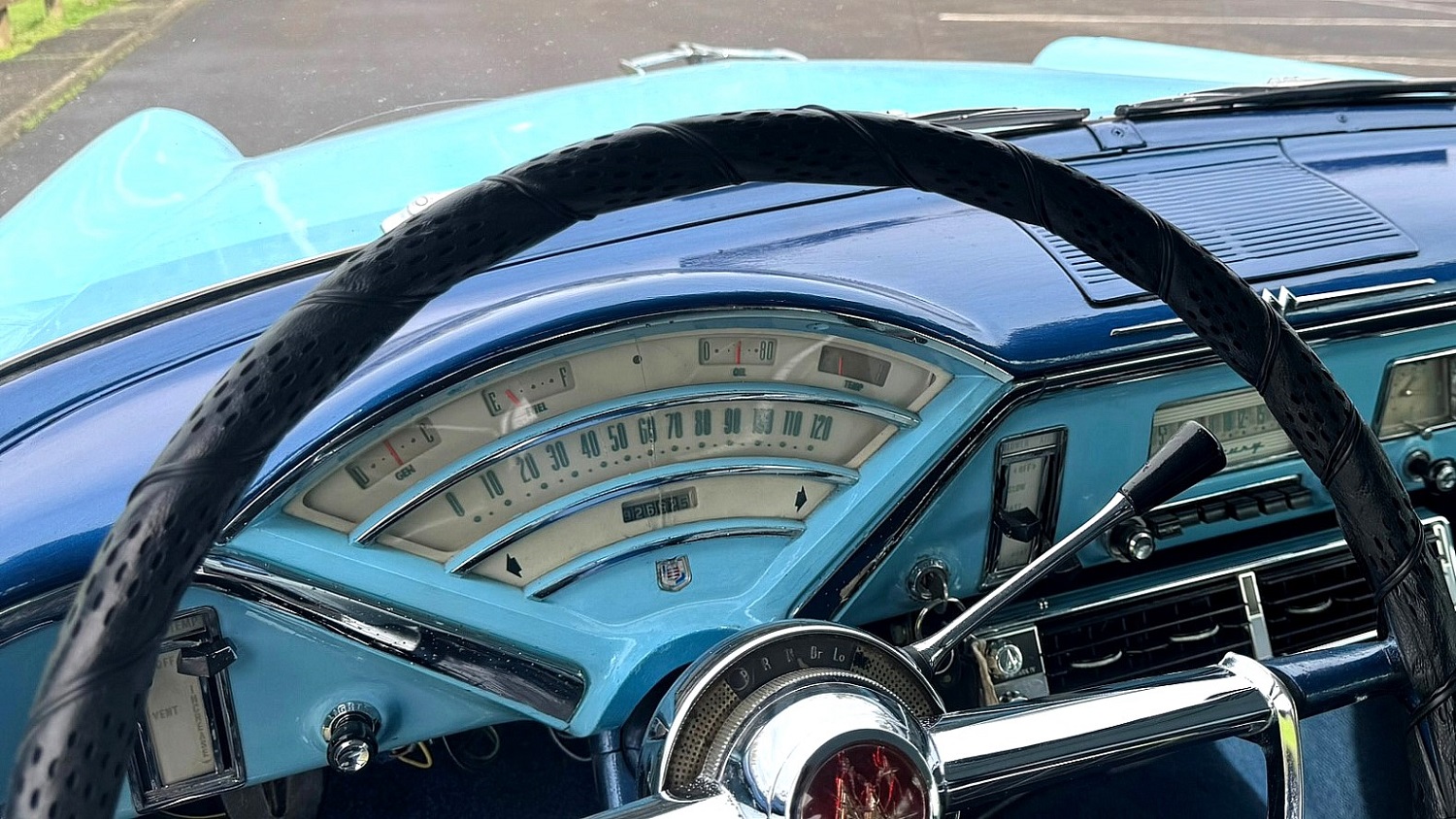

Instrumentation consists of a 120-mph speedometer and amperage, fuel, oil pressure, and temperature gauges. The odometer shows 92,662 miles, but this vehicle is mileage-exempt, according to its title.

Under the hood is a Super-Torque 292ci V8 equipped with a four-barrel carburetor and paired with a Merc-O-Matic three-speed automatic transmission. Power drum brakes provide peace of mind on the way to family outings, car shows, and the hardware store.

If you want peace of mind knowing this 1955 Mercury Custom Station Wagon will be your next car, you need to place the winning bid on it. Do that now because the auction ends on Thursday, October 9, 2025, at 12:30 p.m. (PDT).

Visit the AutoHunter listing for more information and a photo gallery

Toyota’s skillset in building reliable, capable trucks gained a lot of notoriety in the late 1990s and early 2000s. The Tacoma, first launched 30 years ago in 1995 to replace a truck that was simply named “pickup,” has since matured to become the best-selling midsize pickup in the country today. The Pick of the Day is a 2002 Toyota Tacoma 4×4 extended-cab pickup listed for sale on ClassicCars.com by a dealer in Pittsburgh.

Marketing materials for the first-generation Tacoma were playful and fun: one magazine advertisement said, “That feeling of freedom, that feeling of power, that feeling of stupidity after, a spontaneous jungle scream.” It went on to say, “When you’re behind the wheel of a Tacoma 4×4, you can’t help but feel primal.” Toyota boasted about the truck’s V6 engine, its “shift-on-the-move” 4WD system, and its class-leading ground clearance.

This Tacoma is a 79,330-mile, highly original example in beige that is said to be unmodified and rust-free. The listing says, “MaxMotive is pleased to offer this really clean Tacoma. For the year and age of the truck, you can tell it is very well maintained.”

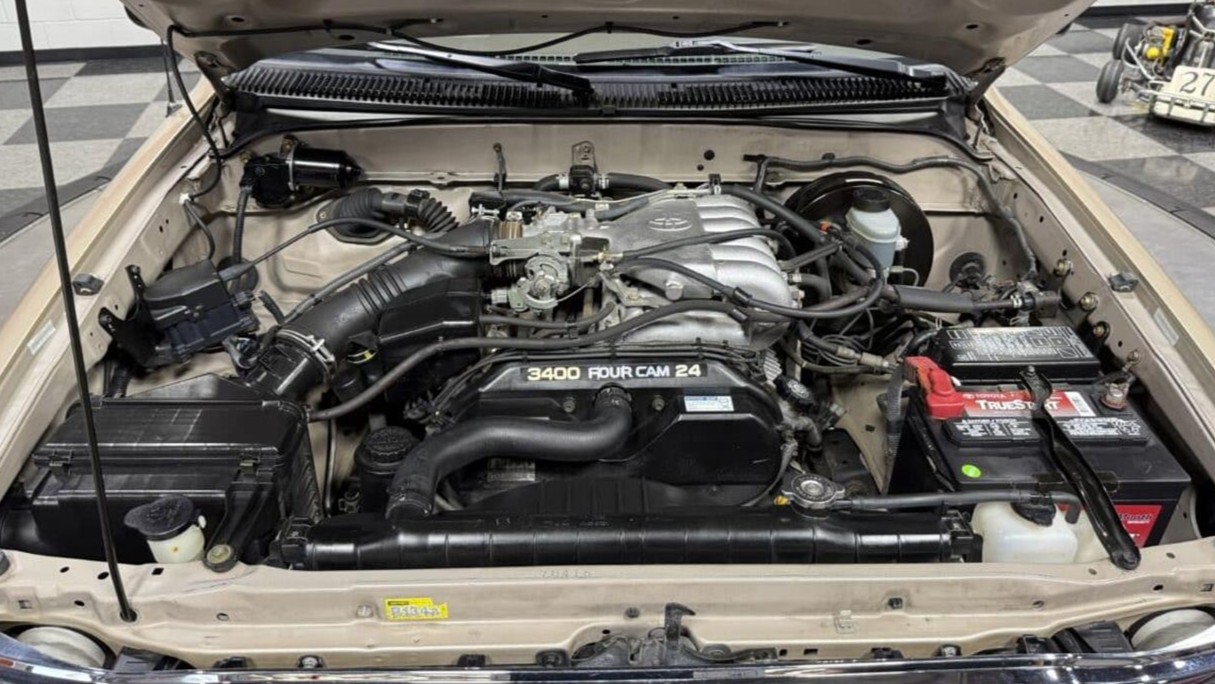

Equipment includes chrome bumpers, side steps, Bridgestone Dueler tires, mud flaps, a sliding rear window, black fender flares, and a spray-in bed liner. The cab is well-appointed, too with bucket seats, a center console, power windows, air conditioning, and AM/FM/CD audio system. Under the hood is a 3.4-liter four-cam V6 that was known under the code name “5VZ-FE.” It was rated at 190 horsepower and 220 lb-ft of torque. A four-speed automatic transmission and dual-range transfer case deliver power to all four corners. The dealer has provided a walk-around video showcasing the exterior and interior.

For those seeking proven reliability, off-road capability, and durability, the Tacoma is a no-brainer. It’s a no-frills truck that some would say is spartan in features, but it has a strong, utilitarian design, strong replacement parts support, and class-leading value retention.

Regarding the price tag: One thing about older Toyota pickups is that they are insanely good at retaining—and even gaining—value. An extended-cab 4×4 V6 Tacoma started out at round $21,000 in base trim when it was new in 2002.

The asking price for this lightly used example today is $27,000.

Click here to view this Pick of the Day on ClassicCars.com

The Rolls-Royce Phantom flagship sedan turns 100 this year. To commemorate the occasion, Rolls-Royce is creating a Private Collection that incorporates three new woodworking techniques that the company’s artisans have never used before.

Rolls-Royce has been pushing the limits of its creativity and craftsmanship, which explains why 2024 was its busiest year for Bespoke builds. The 1-of-1 Phantom Goldfinger honored the 1964 James Bond movie with several custom elements and references. The Phantom Extended Cherry Blossom featured the company’s first use of 3D sculptural embroidery. Most recently, Rolls-Royce created its first-ever hand-painted Starlight Headliner for the space-themed Cullinan Cosmos one-off.

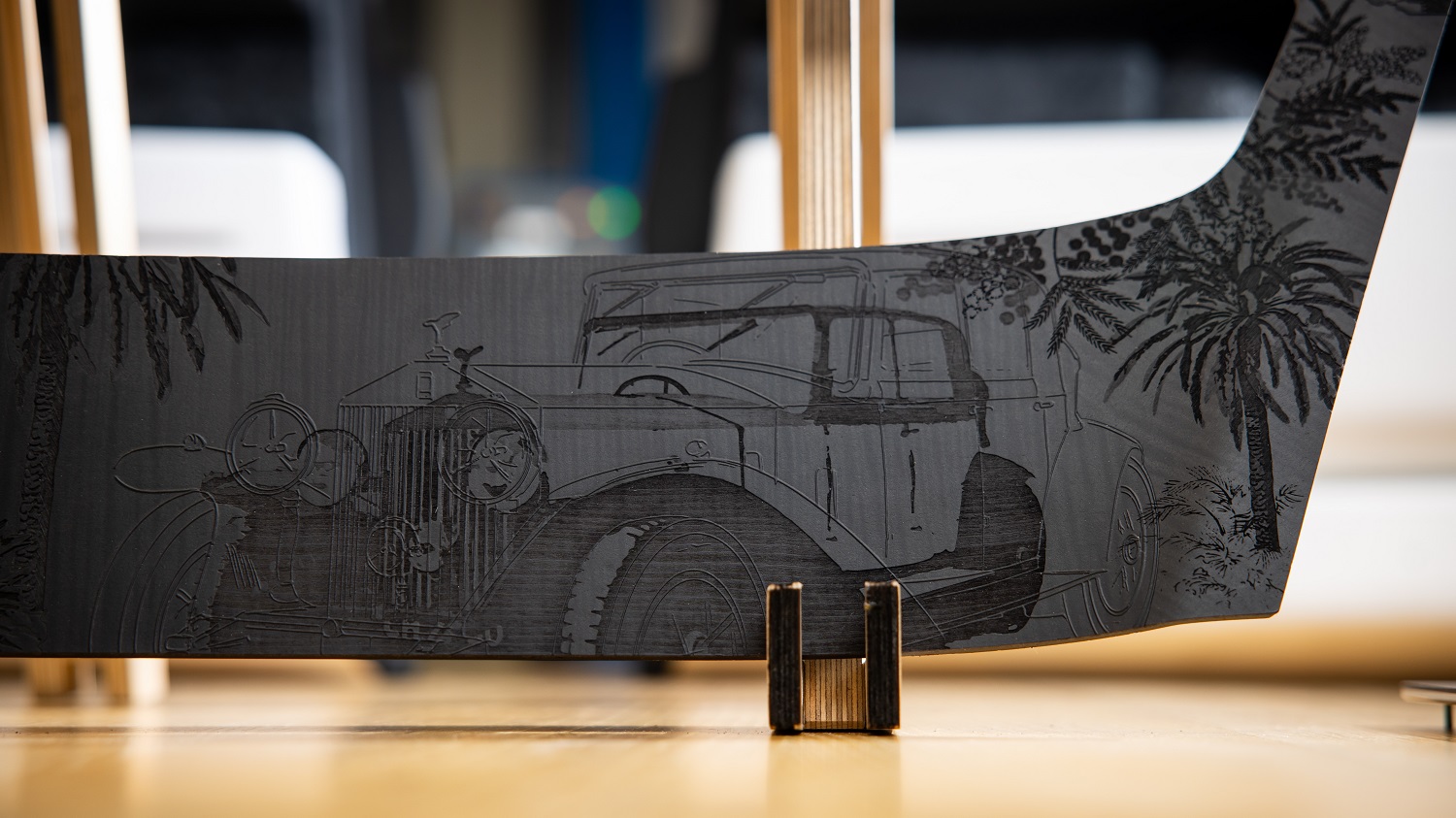

For the Private Collection, Rolls-Royce’s craftspeople spent a year developing wood interior panels made with three firsts for the company: 3D marquetry, 3D ink layering, and gold leafing. They selected sheets of Blackwood veneer, then laser-etched design elements such as maps, landscapes, flowers, trees, and locations significant to the Phantom’s history at three different depths. The lower levels appear darker, producing contrasts in light and color. Instead of cutting holes for the metal speaker grilles, the woodworkers milled the openings directly into the veneer.

The 3D marquetry goes in the opposite direction, adding raised designs to the main surface of the wood so that they can be felt as well as seen. Layers of ink accent the veneers with three-dimensional textures and patterns.

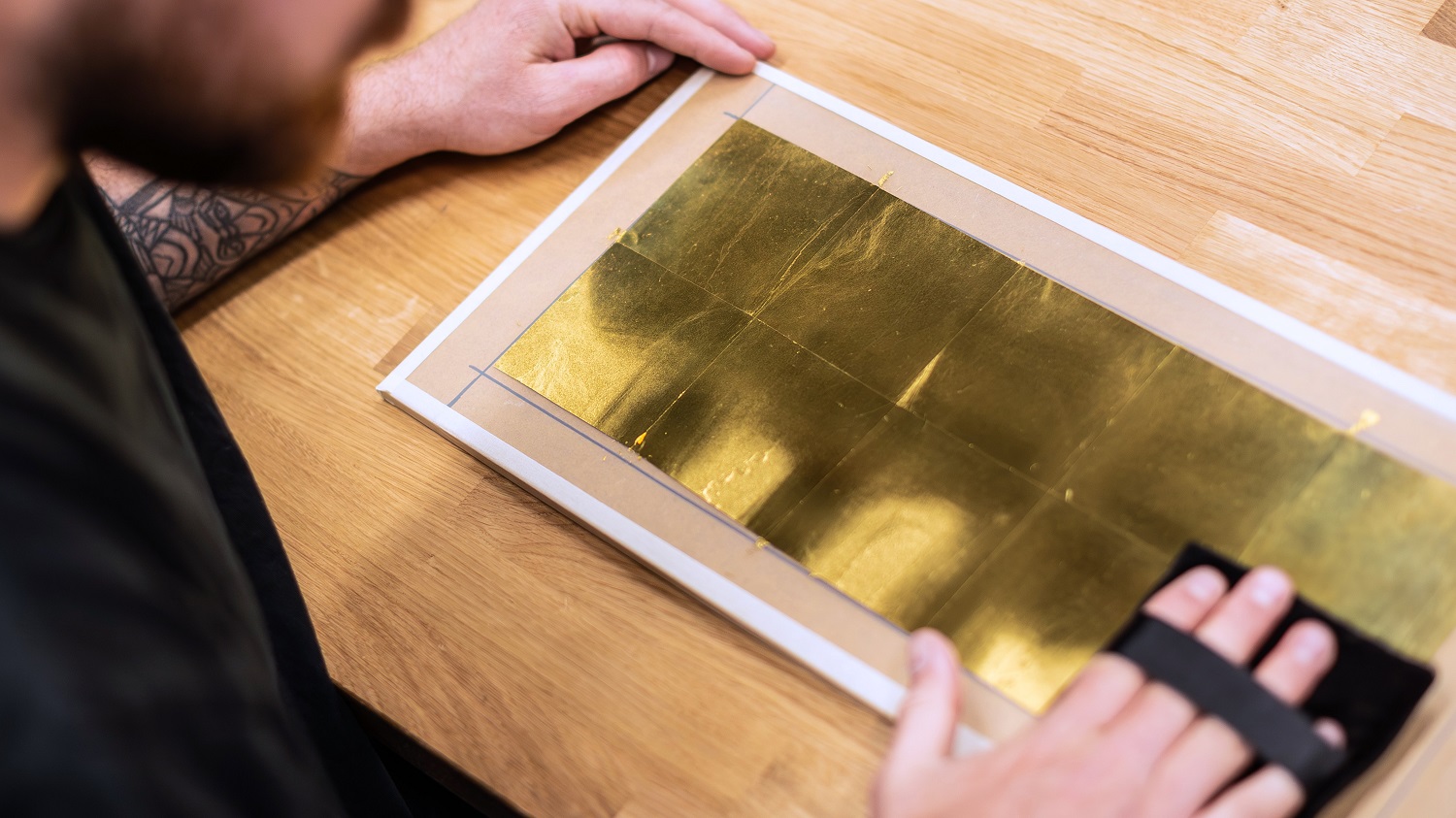

To learn the art of gold leafing, also known as gilding, five people from Rolls-Royce’s Interior Surface Centre took a special course at West Dean College in South East England. Starting with hand-laid sheets of high-gloss 24-carat gold leaf approximately 0.1 micrometers thick, they precisely cut “roads” for the map sections, then set them in the wood veneers.

Speaking of roads, this glimpse at the Private Collection’s interior takes us closer to its official reveal. We have a feeling Rolls-Royce clients will be coming out of the woodwork to get their own pieces of it.

Barrett-Jackson will offer a number of highly coveted Mopars, including a custom, race-inspired 1970 Plymouth Barracuda (preview), during the Scottsdale Fall Auction, Oct. 15-18, 2025, at WestWorld of Scottsdale. Built by BBT Fabrications, a previous Barrett-Jackson Cup winner, the Barracuda is powered by an Indy Cylinder Head Gen II HEMI V8 engine rated at 630 horsepower and features a race-inspired interior. Late-model Mopars on the docket include a 2023 Dodge Challenger SRT Demon 170 (preview) with 48 actual miles.

“Led by their iconic engines, raw power and distinctive styling, Mopar helped ignite a muscle car war in the 1960s that’s still part of the DNA in cars rolling off Stellantis production lines today,” said Craig Jackson, chairman and CEO of Barrett-Jackson. “From restored classics and customs featuring modern performance upgrades to a concept vehicle inspired by the past, our docket of collectible Mopars reflects the legendary status these vehicles cemented into our culture.”

Featured in the lineup of Mopars crossing the block during the Scottsdale Fall Auction is the custom 1970 Plymouth Barracuda (preview) built by BBT Fabrications, a previous Barrett-Jackson Cup winner. This one-off, custom Barracuda is powered by 528ci Gen II HEMI V8 engine rated at 630hp and 660 ft/lbs of torque. The HEMI is equipped with a Holley carburetor, Shaker air cleaner, ceramic-coated long-tube headers and a 3-inch ceramic-coated exhaust system with X-pipe and Flowmaster mufflers. Power is sent through an A&A Transmissions Chrysler 3-speed automatic transmission to a Moser 9-inch rear end with 31-spline axles and Eaton 4.11 gears with posi-traction. The body features new AMD quarter-panels, custom-fabricated floor pans, wheel tubs, firewall and engine bay, shaved marker lights, billet hood hinges and a lift-off decklid.

A custom 1973 Plymouth Barracuda (preview) on the docket is powered by a modern fuel-injected HEMI V8 mated to a high-performance 4-speed automatic transmission. The interior includes a custom leather setup with a custom center console, eight-ball shifter, Sharp steering wheel on a custom column, custom Barracuda digital gauges and a neon blue-illuminated custom start panel with push start, ignition, fuel pump, fan and auxiliary switches. It has approximately 880 miles since the build’s completion.

“Mopar’s HEMI V8 became an icon of the 1960s American muscle car era,” said Steve Davis, president of Barrett-Jackson. “The powerful engine combined with their iconic designs created a new opportunity to put race-inspired vehicles on the road. Bidders will have the chance to own a Mopar, like a 1970 Dodge Challenger R/T (preview) or the ‘BBP Project ’Cuda’ concept car (preview) that’s faithful to its 1970-74 E-Body ancestors.”

For fans of modern muscle, the 2023 Dodge Challenger SRT Demon 170 (preview) with the Hellcat Redeye Widebody option is powered by a supercharged V8 engine producing 1,025 horsepower and has 48 actual miles. The interior includes Demonic Red 170 Laguna seats, the Premium Group with black Alcantara and Laguna materials, vented seats, suede headliner, premium-stitched dash panel, memory seating, carbon-fiber interior accents and an SRT Alcantara steering wheel with red LED logo.

A custom 2023 Dodge Challenger SRT Hellcat (preview) is powered by a supercharged HEMI V8 upgraded with the Hennessey Performance H1000 kit delivering 1,000hp. This Widebody Jailbreak Last Call Edition has factory equipment that includes adaptive damping suspension, Brembo 6-piston brakes, line lock, launch control and the exclusive Jailbreak Package featuring widebody fender flares.

Known as the “BBP Project ’Cuda,” the custom 2008 Plymouth ’Cuda concept car (preview) was designed and built to encourage Chrysler Corporation to bring back the ’Cuda model and the Plymouth brand. Painted in Lambo Pearl Orange, it features an all carbon-fiber body with functional Shaker hood and rides on 22-inch Zenetti wheels and Pirelli tires. This concept ’Cuda was shown at the 2007 SEMA Show in Las Vegas, where it made its official debut.

Rotisserie-restored to its factory Bright Red paint, the custom 1970 Dodge Challenger R/T (preview) features a new vinyl top and black interior with every component upgraded. It is powered by a HEMI engine mated to the rebuilt matching-numbers 4-speed manual transmission. The interior is complemented with air conditioning, Rallye instrument gauge cluster, pistol-grip shifter and an Out of Sight Bluetooth stereo system.

Those interested in consigning their vehicles with confidence for the Scottsdale Fall Auction are welcome to submit their application online. In addition, bidder registration is open, with three packages to choose from, upgrades for Muscle Lounge access and Hammer High Tops. Throughout the four-day Scottsdale Fall Auction, children ages 12 and under enjoy complimentary admission with a paying adult. General admission tickets for students ages 13 through college-age are $10 and adult ticket prices start at $28.

Be a part of Barrett-Jackson’s online conversation with #BarrettJackson and #BJAC on Facebook, X, Instagram and YouTube.

There is something pure and simple about the Chevrolet Nova. Once the unsung hero of GM muscle cars, the Nova SS has become much more desirable and is still the easy entry point into that world of performance (the pricier Chevelle SS 396 really doesn’t offer anything that the Nova doesn’t).

The fully restyled third-generation Chevy II/Nova was launched in 1968. It rode on a 111-inch wheelbase, which was only one inch shorter than that of the two-door Chevelle. The Nova also had a new subframe assembly similar to the one used by the Camaro.

The Nova SS introduced in 1968 was a high-performance model, not the version that was just bucket seats and trim as in previous years. In fact, it was one of the smallest muscle cars ever built by any brand in Detroit.

Today’s AutoHunter Spotlight is a 1971 Chevrolet Nova Coupe. It is an SS tribute, with all the correct SS trim added to a car that was originally a base six-cylinder model.

The seller describes this 1971 Nova as being powered by a 350ci V8 backed by a three-speed automatic transmission. The car is finished in its original color of Classic Copper over a black cloth and vinyl interior. It is offered by the selling dealer in Oregon with the original window sticker, Protect-O-Plate, documentation, manuals, receipts, and a clear title.

The seller notes that the car underwent a complete restoration, at which time it was converted into SS specs. Judging by the many provided pictures, it looks as if it was done very well, with the Classic Copper paint and the chrome trim appearing to be in great shape. The car rides on correct 15-inch Rally wheels clad with 215/60 Petlas radial tires.

The interior of this Nova is just as nice. The front bench seat looks to be in excellent shape, with the factory-style vinyl and cloth in nice condition. Interior upgrades include a correct SS steering wheel, Vintage Air air conditioning system, and an awesome Dakota Digital gauge cluster. This is the perfect Nova to show or use on fun cruises. I think it would be a great Hot Rod Power Tour car.

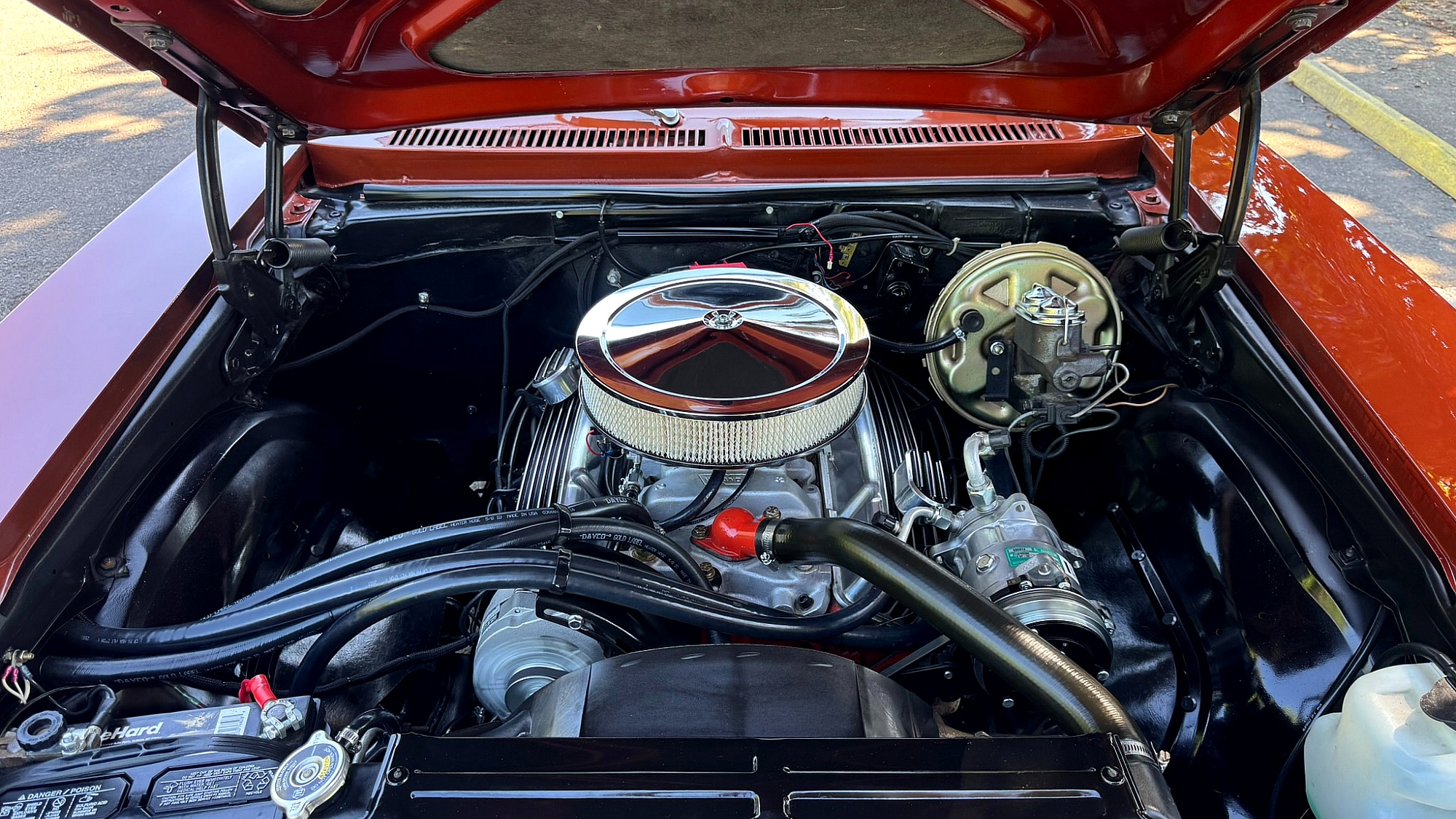

Under the hood is a small-block 350ci V8 with a four-barrel carburetor, an aftermarket Weiand aluminum performance intake manifold, and chrome valve covers. Recently, this car received a new power steering pump and hoses, new alternator and regulator, new belts, new radiator, new fuel tank and sender, new motor and trans mounts, and new transmission pan. All that makes me think this car is the kind you could buy at the auction and drive home.

As I said at the beginning of this AutoHunter Spotlight, the Nova is a great entry point into the world of GM muscle cars. It’s capable, simple to work on, and easy to find parts for. It is the perfect first-time muscle car and still a good value. If you are interested in this 1971 Chevrolet Nova SS tribute, act fast and make a bid before it ends up in someone else’s garage because the auction for it ends on Wednesday, October 8, 2025, at 12:15 p.m. (PDT).

Visit the AutoHunter listing for more information and a photo gallery

Peruse social media and you may find someone opining, “Muscle cars died after 1971!” while failing to acknowledge an anomaly of the low-compression era, the 1973-74 Super Duty 455 Firebird. However, the truth is that there were other cars that still offered respectable performance, our Pick of the Day being one. This 1974 Dodge Charger Rallye is listed for sale on ClassicCars.com by a dealership in Clearwater, Florida.

Beginning with 1972, the whole American automobile market was running on lowered compression to allow for low-lead and unleaded fuel. Certain manufacturers and brands fared better than others. Ford offered the Mustang with a 275-horsepower 351 HO—basically a low-compression Boss 351—but it was only available for several months, and it never was available for any other FoMoCo model. Otherwise, the 351 Cobra Jet (266 horses for the pony cars, 248 for mid-sizers) somewhat did the job, and Ford simply didn’t entertain milking the 205-horse 429-4V for all it was worth.

American Motors did a decent job of offering “hot” 360 and 401 engines for the Javelin, offering a contemporary 220 and 255 net horsepower, respectively. Buick continued to offer 455s with as much as 270 horses. Chevrolet had a strong Z/28 350 with 255 horses, a 402 with 240, and a 454 with 270. Oldsmobile and Pontiac excelled, both offering 455s with up to 300 horsepower while offering lesser versions, if not a 250-horse 400 for Pontiac.

What about Chrysler Corporation? As the company with the strong reputation for engineering, Plymouth and Dodge was competitive with the industry. The 340 was rated at 240 horsepower, while the new 400 put out 255 horses. Notwithstanding the quickly-cancelled 440 Six Pack, the 440 four-barrel was rated at 280 horses.

Despite the whining by the “muscle cars died after 1971!” crowd, you’ll find that the engines that arrived in 1972 generally continued to stay pat through 1974. For example, the 440 four-barrel continued to be rated at 280 horsepower, then falling by five to 275 for 1974. Considering the Super Duty 455 was rated at 290 horses, this was fair.

Before you is the last of the classic Chargers, this one being this “JL6” Aztec Gold metallic 1974 Dodge Charger Rallye. The “A57” Rallye Package was available on the Charger coupe and hardtop (the former included a cheaper interior and fixed rear quarter windows) and included Power Bulge hood, Rallye Cluster, black longitudinal tape stripe, hood pins, rear anti-sway bar, and G70x14-inch white-letter tires. Add the 440 engine and you’d have the closest thing to a Charger R/T this side of 1971, but a whole lot rarer—only 206 U.S.-spec Charger Rallye hardtops were built like this. “The car’s original engine is in original condition and has all the factory stock equipment like the intake manifold, carb, cast iron exhaust manifolds, valve covers, air conditioning, and most other engine parts and accessories,” says the seller. The interior is equally as intriguing, as it’s one of the few built with the “N1YW” Aztec cloth interior. This one is the optional cloth and vinyl bench seat, rather than the sportier high-back buckets with the “buddy seat” and arm rest. “All the rest of the interior looks like it did when it left the showroom with the factory stock door panels, dash and gauges, headliner, seat belts, carpeting, and radio.”

Have you priced a Charger R/T lately? Insane. But a 440-powered Charger Rallye is 7/8th the same car, and it still has the same sleek sporty style in spades. For $69,990, you can show the naysayers that there’s nothing wrong with Malaise.

Click here to view this Pick of the Day on ClassicCars.com