Now more than ever U.S. consumers are looking for ways to cut costs and save more of their hard-earned money. Recently a growing number of classic and modern collectible vehicle owners have discovered that for years now they have been overpaying for auto insurance. The good news is that these same auto enthusiasts have saved some serious dollars with about 5 minutes of effort.

Does Your Vehicle Qualify? Let’s Find Out!

For several years now U.S. drives have been seeing their auto insurance rates steadily climb year after year, and many auto insurance companies are betting on the typical driver not noticing how these increases have quickly added up and hurt their wallet. But according to the Consumer Price Index, the cost of auto insurance has risen six times faster than inflation over the past three years. What is driving these surging costs? Well over the past few years many auto insurance companies have been working hard to recover from their recent catastrophic losses. Beginning in 2020, there were more frequent accidents, faster-than-normal speeding and instances of drunk driving surged. This all caused a spike in crash severity, which led to more catastrophic vehicle and injury claims placed on auto insurers. Moreover, materials, parts, and labor shortages during that same time frame caused repair costs for claims to climb like never before. In response, auto insurance companies began raising rates with little relief in sight. In effect, collectible vehicle owners and good drivers have been quietly subsidizing the recent losses felt by insurance companies.

Classic & Modern Collectible Vehicle Owners Among the Most Impacted

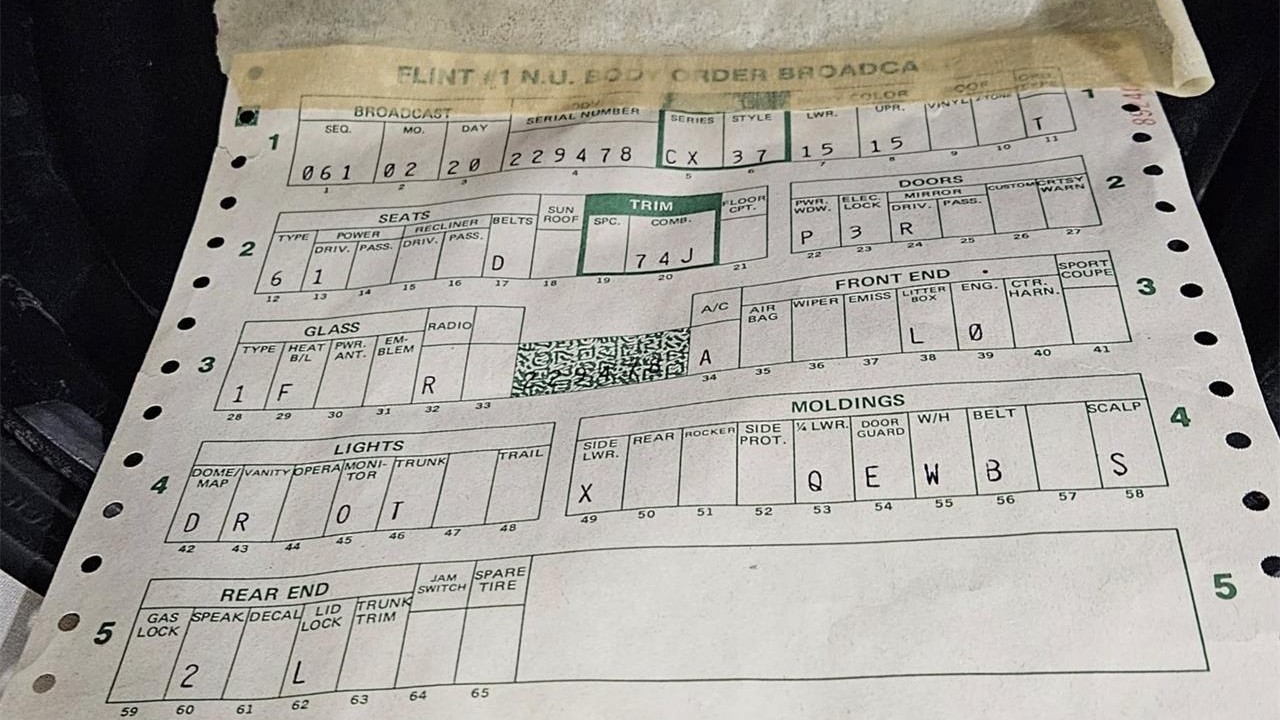

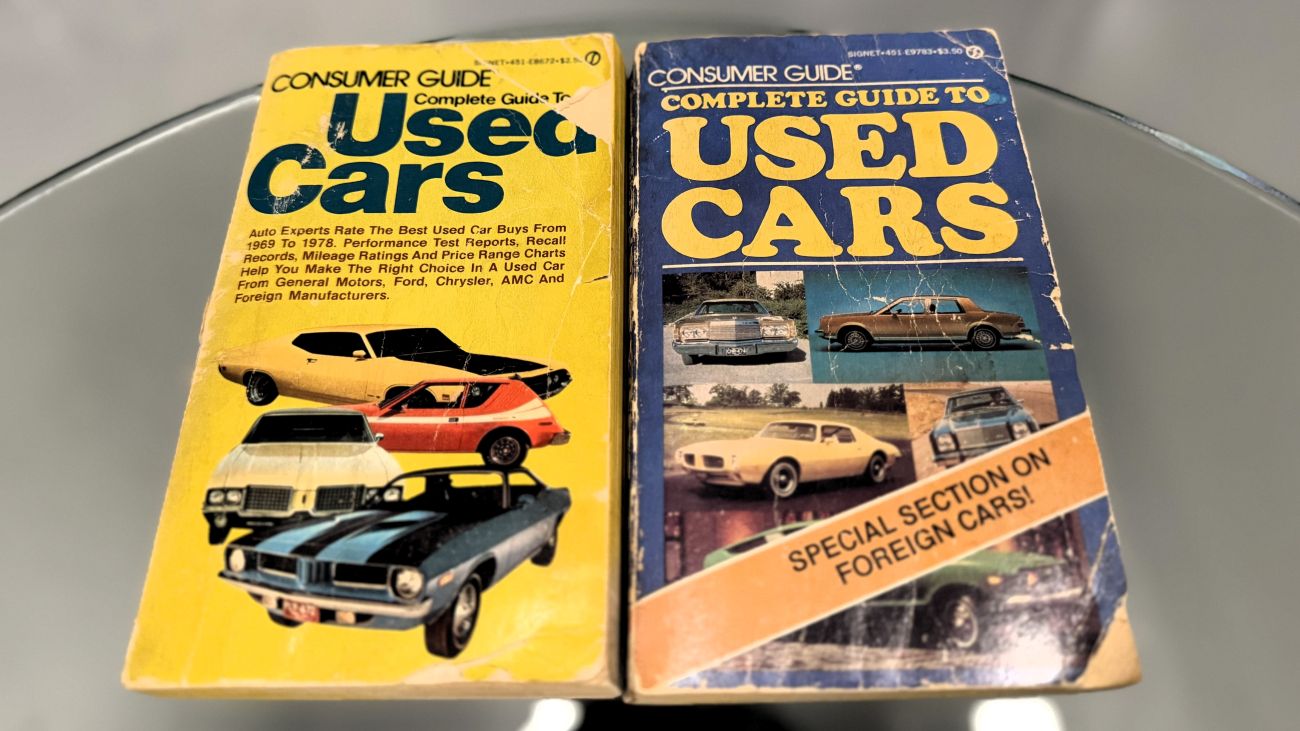

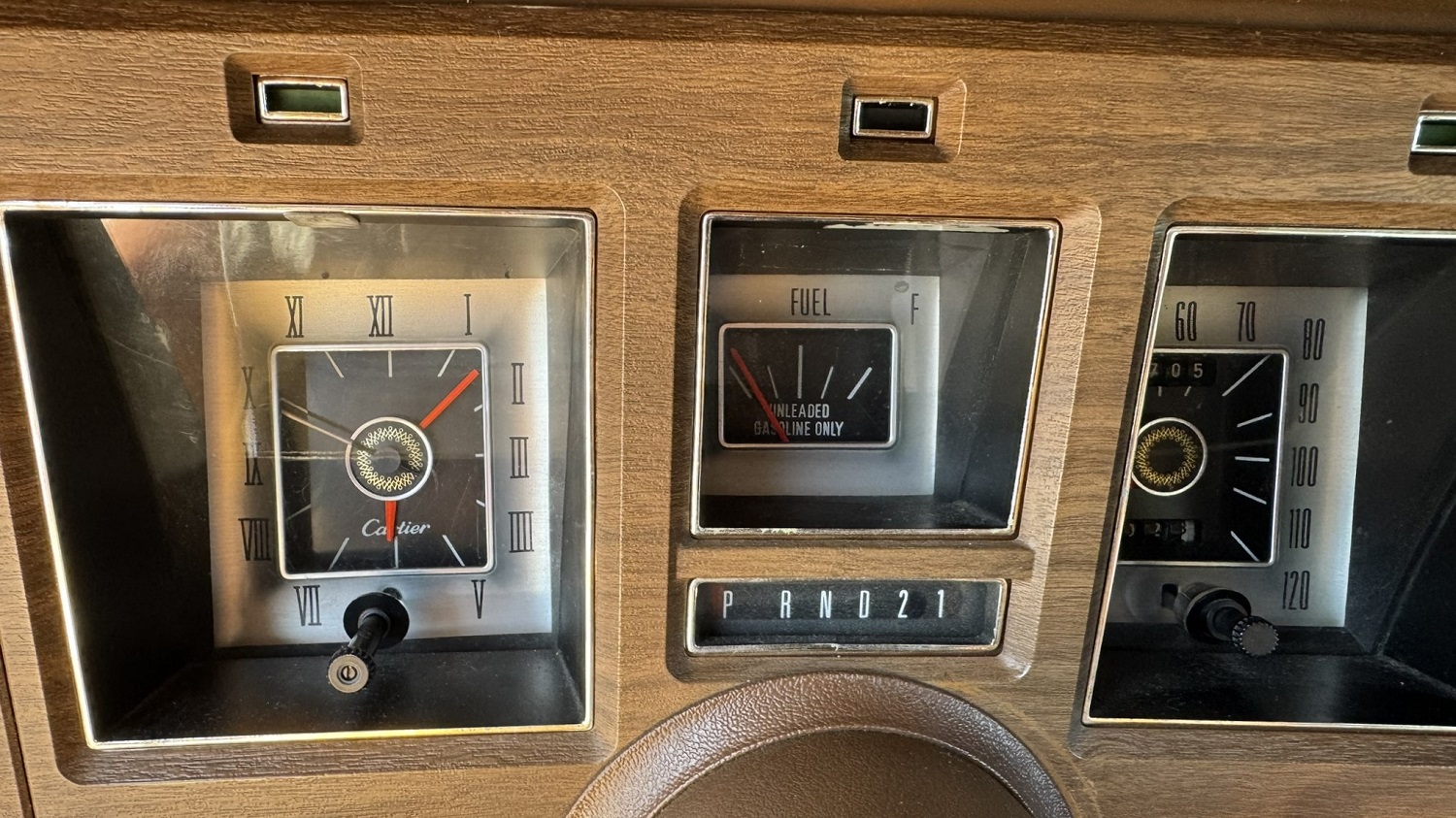

Unfortunately, owners of classic, antique, and custom cars or trucks are among the most severely affected by these insurance cost increases. These collectors face a double inequity: Not only are auto collectors likely paying more than they should be given their reduced risk profile, but the auto insurance coverage they do buy is often radically insufficient. This unfortunate truth will only be discovered when they need to make a claim.

Of the 40 million+ collector vehicles in the United States, the vast majority are insured by standard auto insurance programs. These programs were never designed to protect classic and collector vehicles; they were designed for daily drivers. Standard auto insurance rates are calculated based on all the risks that come with typical daily driver usage, meaning more time on the road doing things like commutes and running errands in all types of weather and traffic conditions. These inflated standard insurance rates do not account for the fact that collector vehicle owners are statistically less likely to get into an accident or file a claim. For them, all rides share the same risk profile as a daily driver and their inflated insurance rates reflect that inaccuracy.

The other scenario at play here is the inadequate coverage many of these insurers offer classic vehicle owners. Even for minor repairs, standard auto insurance programs do not guarantee that they will cover original parts or that their approved body shop network has the expertise necessary to repair these types of vehicles.

Discover What The Right Coverage Looks Like

Classic & Modern Collectible Vehicle Owners Are Flocking To New Program

In all this turmoil there does seem to be some good news for classic car and truck owners, and word is quickly spreading. Recently the auto enthusiast community has been buzzing about a program being offered by the Dallas-based collector vehicle insurer OpenRoad. Customer testimonials from owners previously covered by standard auto insurers, as well as many previously insured by classic car insurance providers, continue to roll in highlighting significant savings, better coverage, and superior customer service.

OpenRoad has built a truly unique collector vehicle insurance program that all starts with pricing. Not only do they provide significant savings for drivers with great driving records, but they also account for the reduced accident frequency associated with collector vehicles. Both often result in far lower insurance rates overall. But OpenRoad goes further on reduced pricing, offering additional discounts to car club members as well as any customer who transfers their coverage from another classic car insurer.

Setting a New Bar For Classic & Collector Vehicle Insurance

OpenRoad exceeds what many other programs out there can offer. In addition to getting all the coverage you’d expect with any auto insurance policy— think comprehensive, collision, uninsured motorist, and the like — every OpenRoad policy comes with several protections tailored to car collectors. Their agreed value policy guarantees that the insurance payout you’ll receive in the event of a total loss equals the actual worth of your classic car, rather than a depreciated value that most insurance programs use. This guarantees that you’re covered for the true value of your ride, considering the time, effort, and investments you put into your vehicle as well as its condition and rarity.

OpenRoad is also setting a new bar when it comes to coverage for repairs. Under their program you know that if you need to file a claim the repairs will be done right. Not only will repairs be performed with OEM parts specifically tailored to your vehicle, but you’ll also get to choose a repair shop you know and trust, one that specializes in collector vehicles and classic car restorations. This is another differentiator from standard auto insurance programs that often do not guarantee coverage for OEM parts and rarely let you pick a shop outside of their approved body shop network.

OpenRoad also includes a generous emergency roadside cost reimbursement program at no additional cost as well as coverage for the relocation and temporary storage of your ride in the event of major disasters such as hurricanes and wildfires.

Delivering Superior Customer Service & Specialized Coverage

With so many auto enthusiasts making the switch to OpenRoad, it seems that they have found everything that they have been looking for in a classic auto insurance provider. Just check out these recent customer reviews:

- Almost half the price (of) your competitors for equal coverage.”

- “Better coverage for less cost than other classic car insurance companies.”

- “They made it easy for me to switch from my old insurance policy to new one and at less than half the price!”

- “Not only did they match our previous collector car insurance, they beat it even after adding another vehicle to the policy! They are rockstars! Would recommend to everyone!

- “To my total surprise I got more coverage for a fraction of what I have been paying.”

Beyond the significant cost relief, many customers also point to the excellent customer service they received with reviews that include statements such as, “The team went above and beyond to help us,” and, “Overall, the best experience I’ve had setting up insurance.” That’s some high praise for an auto insurance company.

Rapidly Expanding Across the U.S.

To keep up with the massive market demand that they’ve seen, OpenRoad has been rapidly rolling out its insurance program across the U.S., quickly growing coverage availability to 25 states. Don’t reside in one of their currently live states? Don’t worry, the brand plans to add coverage across several more states by the summer of 2025. You can also sign up for their launch newsletter and get notified as soon as coverage is available for your area.

Get your quote today and see how much you could save in about 5 minutes.