Whenever I hear or read the words “spared no expense,” I immediately think of the famous quote by the character John Hammond in the movie Jurassic Park. Whether related to theme parks, real estate, travel, or cars – I think we can all agree that it’s easy to lose control of budgetary restrictions when you get going on a project. Here’s a car with a six-figure price tag that still probably cost more to build than it’s being sold for:

The Pick of the Day is a custom 1936 Ford two-door coupe listed for sale on ClassicCars.com by a private seller in Lincoln, Nebraska.

The listing begins, “Built from the frame up by multiple craftsmen, this one-of-a-kind classic collector’s gem was restored sparing no expense – and no detail. Pictures do this car little justice. You have to see it for yourself!”

Where do we even begin? First and foremost, the color ranks in at least the top five of any that I’ve ever come across in having written for The Journal for the last nine years. The seller says it’s a hue from House of Kolor, and it’s called “Burple” – presumably because it’s a combination of blue and purple. The car’s roof was chopped by 3.5 inches in the front in order to give it a streamlined look. Exterior features include a custom frame, a 1936 all-steel body, new hood side panels, shaved door handles, “swan” mirrors, teardrop-style 1939 taillights, and a 1937-style hood. It seems there isn’t much that’s original, but that’s the whole point of a restomod anyway: it’s a one-of-a-kind car throughout.

Even the interior was outfitted with a long list of modern niceties like tinted power windows, keyless entry, a backup camera, a custom sound system, LED lighting, aluminum door panels, a Vintage Air HVAC system, and an all-leather two-tone interior.

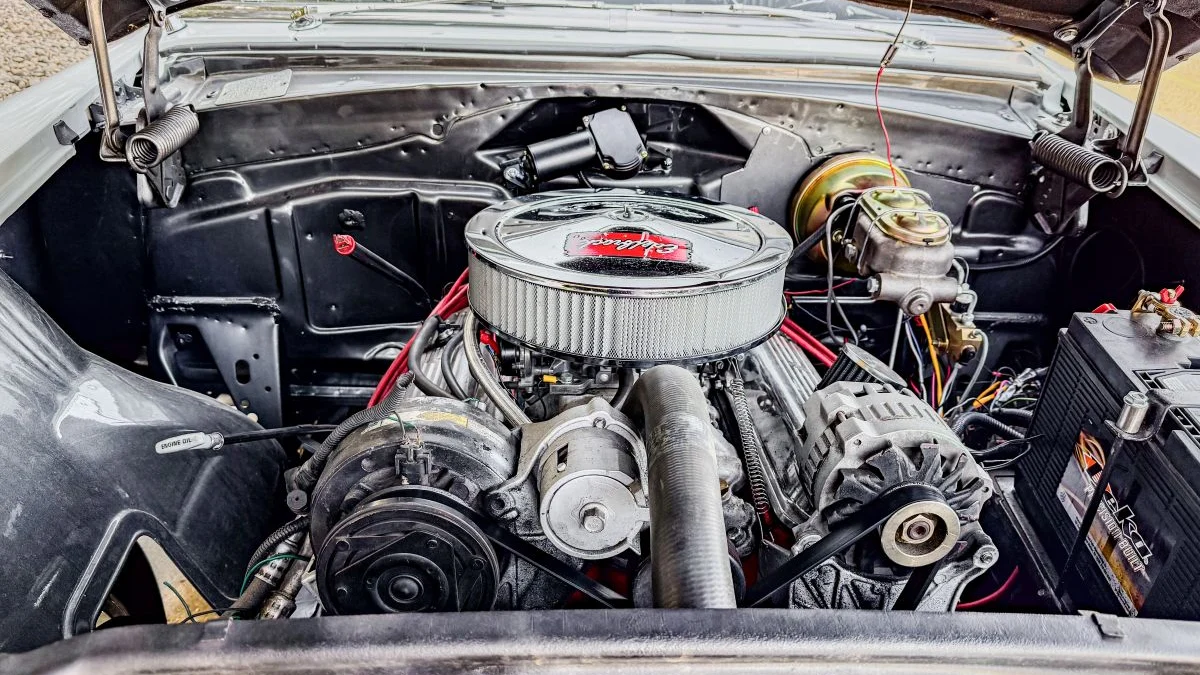

Momentum comes from a BluePrint 383ci high-performance stroker V8 that was rated at 430 horsepower, paired with a 700R four-speed automatic transmission. Features include aluminum heads, a roller cam, a cast steel crank, a four-bolt main, Hastings moly rings, and a heavy-duty timing set. With a spec sheet like that, I can imagine this car sounds (and drives) just as sweet as it looks.

The seller says, “This hot rod was built to sustain its classic style but meet every accoutrement of the 21st century.” As for the expense, the price tag might give some people sticker shock, but having restored a few cars myself, I can attest that it adds up quickly.

The asking price is $150,000 or best offer.

Click here to view this Pick of the Day on ClassicCars.com