Your vehicle’s cooling system is more than just a radiator, water pump, thermostat, fan, and coolant. Well, OK, it is exactly that, but there is a lot more to an effective cooling system than just the parts, they need to be matched to properly cool the engine (and transmission/oil) consistently without overheating. There are so many variables in cooling system design that can cause major headaches. You may think you have a serious engine issue, but you may just have the wrong radiator cap.

We spent some time speaking with Phil Cochran of U.S. Radiator in Gadsen, Alabama, about automotive cooling systems. U.S. Radiator has been building the best in radiators for over 50 years, using American-made parts and materials. When it comes to radiator and cooling system components, you really do not want to skimp on the quality, the life of your engine depends on it. If you have a project that you need assistance with keeping it cool, call U.S. Radiator at 800-421-5975 so their techs can help you solve the problem and get your temps down where they should be.

Are All Radiators The Same?

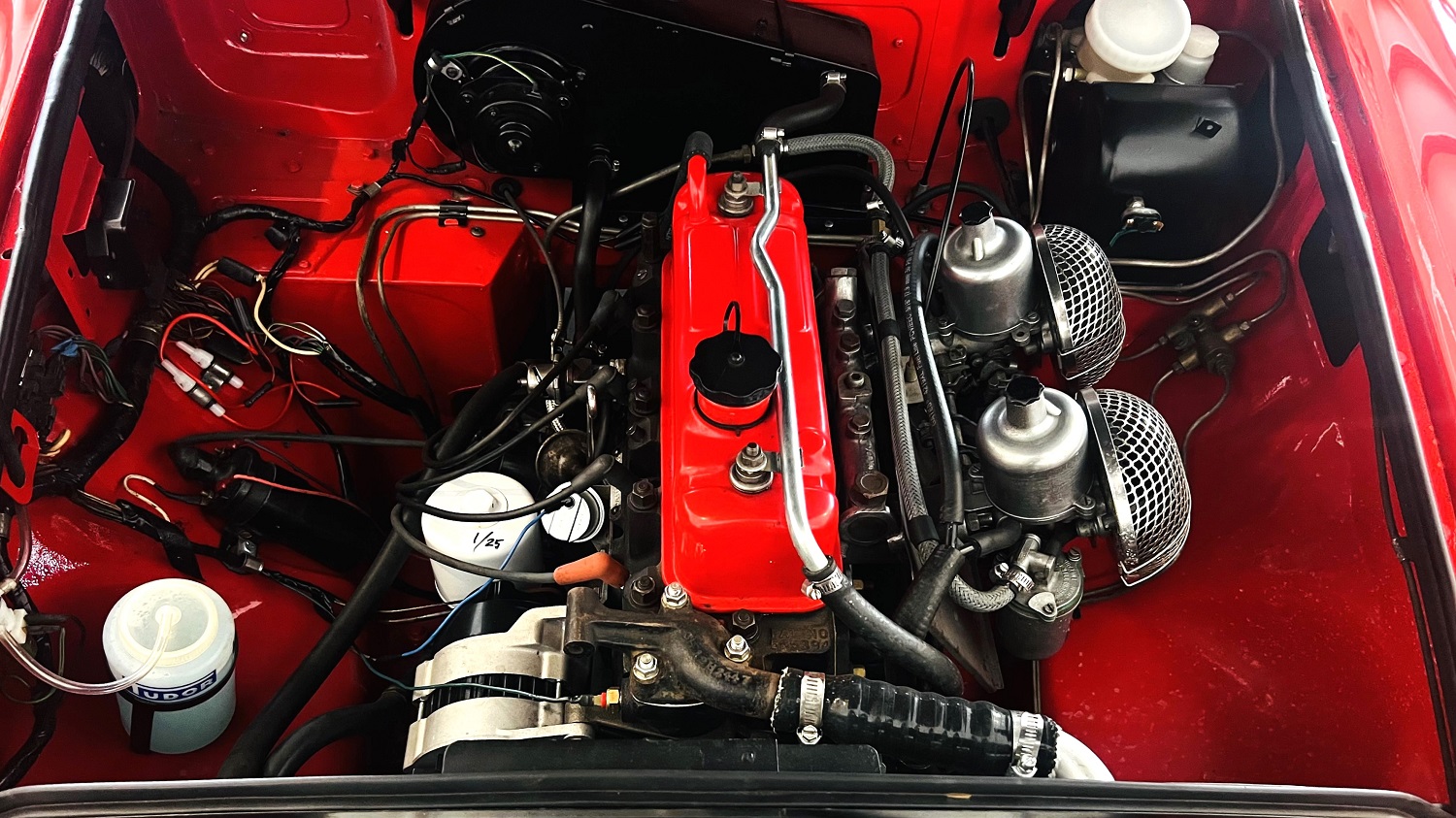

The simple answer is absolutely not. There are so many different styles and types of engine radiators, it can get confusing, but there are a few styles that are the most common. Prior to the 1980s, pretty much every radiator was made from a copper-brass alloy, which offers the best heat transfer rate. The problem with copper-brass (CB for short) is that the tubes have to be thicker and they use solder to bond each tube to the end plate. This makes CB radiator cores thicker, taking up more space. In the mid-80s, copper and brass became harder to get, so OEMs switched to aluminum radiators. Aluminum also conducts heat well, just not quite as well as CB. The difference is that aluminum tubes are much thinner, so you can fit more rows of tubes in the same space as a CB core.

Why Should I Choose A Copper-Brass Radiator?

CB cores can be repaired, as they are soldered together, where aluminum cores are much harder to repair pinhole leaks. CB cores are not affected by electrolysis, so if you maintain the cooling system and flush it every 2-3 years, your radiator should last a very long time. The main reason to select a CB radiator is the appearance. If you want to keep the original appearance, then a CB radiator does that. U.S. Radiator can even re-core your original radiator with a modern core that has better flow but retains the original tanks, which is important for vehicles built in the 1950s and older, as the VIN and data plates were typically affixed to the radiator tank.

Why Choose An Aluminum Radiator?

Aluminum radiator cores have more rows of tubes with thinner walls, making them more efficient when compared to the same size CB core. “We can move more coolant in a smaller space with aluminum” Cochran told us, “If we leave it based on space alone, we go with aluminum.” That doesn’t mean that aluminum cores are perfect, they do need to be protected from electrolysis, which is an electro-chemical reaction that is present in every engine cooling system. The fix is to run a sacrificial anode in the cooling system. Aluminum radiators are difficult to repair, so when they fail it is a replacement job.

What Is The Difference Between Downflow and Crossflow Radiators?

Most radiators were downflow until the mid-60s, when OEMs began using crossflow designs, though many trucks kept the downflow design into the 1970s. A downflow design has tanks on the top and bottom of the radiator. Water flows from the pump to the top of the radiator, filling the tubes and flowing downward to the bottom tank, where it is pulled back into the engine. When comparing apples to apples, if the cores are the same size and design, along with the tanks, then there is not much difference in efficiency. Crossflow radiators have several benefits that downflow units don’t. Cooling systems are pressurized, and the radiator cap is there to manage the pressure. Downflow radiators can only have the cap on the hot side (where hot coolant exits the engine), so this is the highest-pressure area, allowing the cap to vent prematurely. This is a small benefit, but worth mentioning.

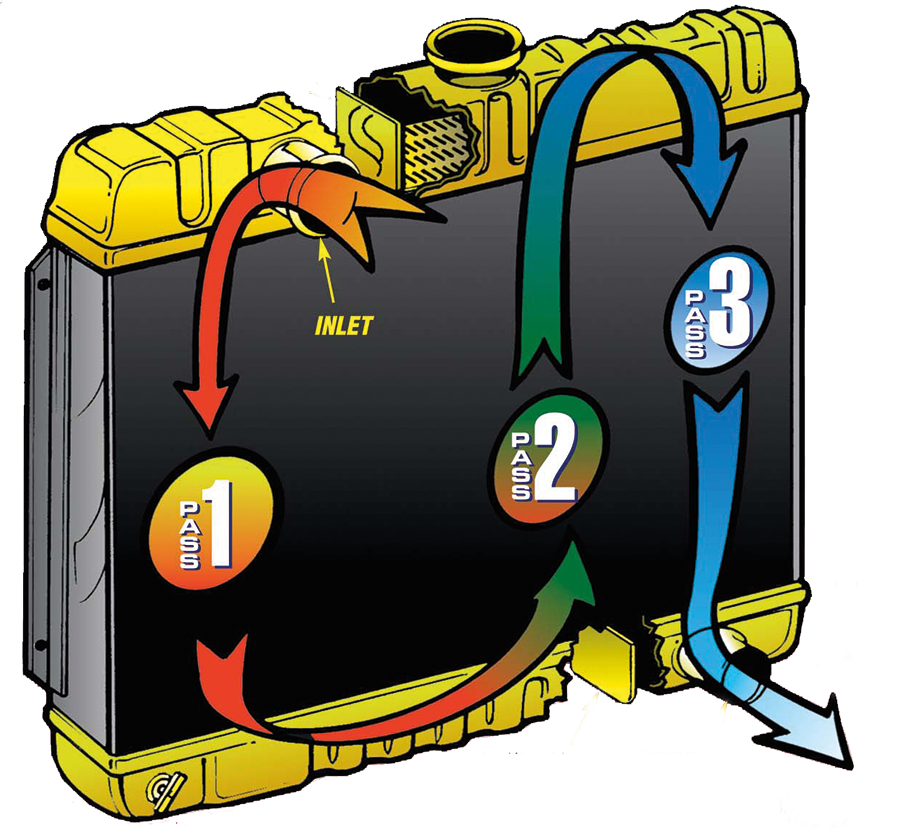

What Is A Dual or Triple Flow Radiator?

In many cases, you can order a new radiator that looks like a typical radiator but is divided internally into two or three sections. A typical radiator flows all the coolant through the entire core in one pass. A dual or triple flow core splits the core so that the coolant flows through each section of the core, giving the coolant more time to transfer heat, making it far more efficient. The U.S. Radiator Tripleflow option can drop engine temps up to 20%, which is a huge gain. If you have a hot-running engine, this could be the difference you need.

Why Are There So Many Different Radiator Caps?

If you have ever been to a parts store, you probably noticed about a million radiator caps. While some of this is due to OEMs not using a standard cap size (Asian cars have very small caps for example), there is also a difference in the pressure relief. Heat means pressure, and your cooling system has a limit on how much pressure it can contain; this is where the cap relief valve vents to purge that excess pressure. When you get steam pouring out from under the hood, that is the cap venting.

“How your cooling system pressure is managed is a critical component to the overall design” says Cochran, “Open or closed recovery systems change the pressures inside the main cooling system.” The first closed-loop cooling systems for automobiles came out in the late 1930s, but they were not standard until the late 1980s. Even GM has used both systems in the same model with different packages. For example, a 1968 Buick GS had a standard closed system, but that would be an optional accessory on a Skylark. There are different pressure rates for various engines and cooling system types. The most common are 15 PSI for closed systems, and 7-15 PSI for open systems. Some race cars use 20- to 30-lb. caps, but that is not for the street.

An open system vents to a bottle, can, or to the ground (not very environmentally sound!) and uses a single-seal cap. When the coolant pressure exceeds the cap rating, the valve opens, sending coolant into the overflow tank. Closed systems are much more efficient. These use a double-acting cap which purges extra pressure and draws reserve coolant into the system when it is cold. The tank on a closed system is an expansion tank, serving to maintain the coolant level in the system when hot and cold.

Why Does Radiator Cap Pressure Matter?

“A change in pressure of 1 psi results in a 3-degree change in temperature” says Cochran, “If your engine calls for a 15 PSI cap, but the one that is actually on the radiator is only holding to 7 PSI, you can see engine temperatures 27 degrees higher than you should.” The opposite is also true, as water boils at 212-degrees at sea level, but at 6200 ft, it boils at 200, this is the difference in pressure. While a higher-pressure cap will push the boiling point higher, the pressure inside the system can reach unsafe levels. Remember, the hoses, pump, and gaskets are under the same pressure and temperature, ballooning the hoses with higher pressures is a recipe for disaster. Another key point on caps- Stay away from the cheap overseas caps, buy a quality US-made cap so you can be sure it will actually vent at the correct pressure.

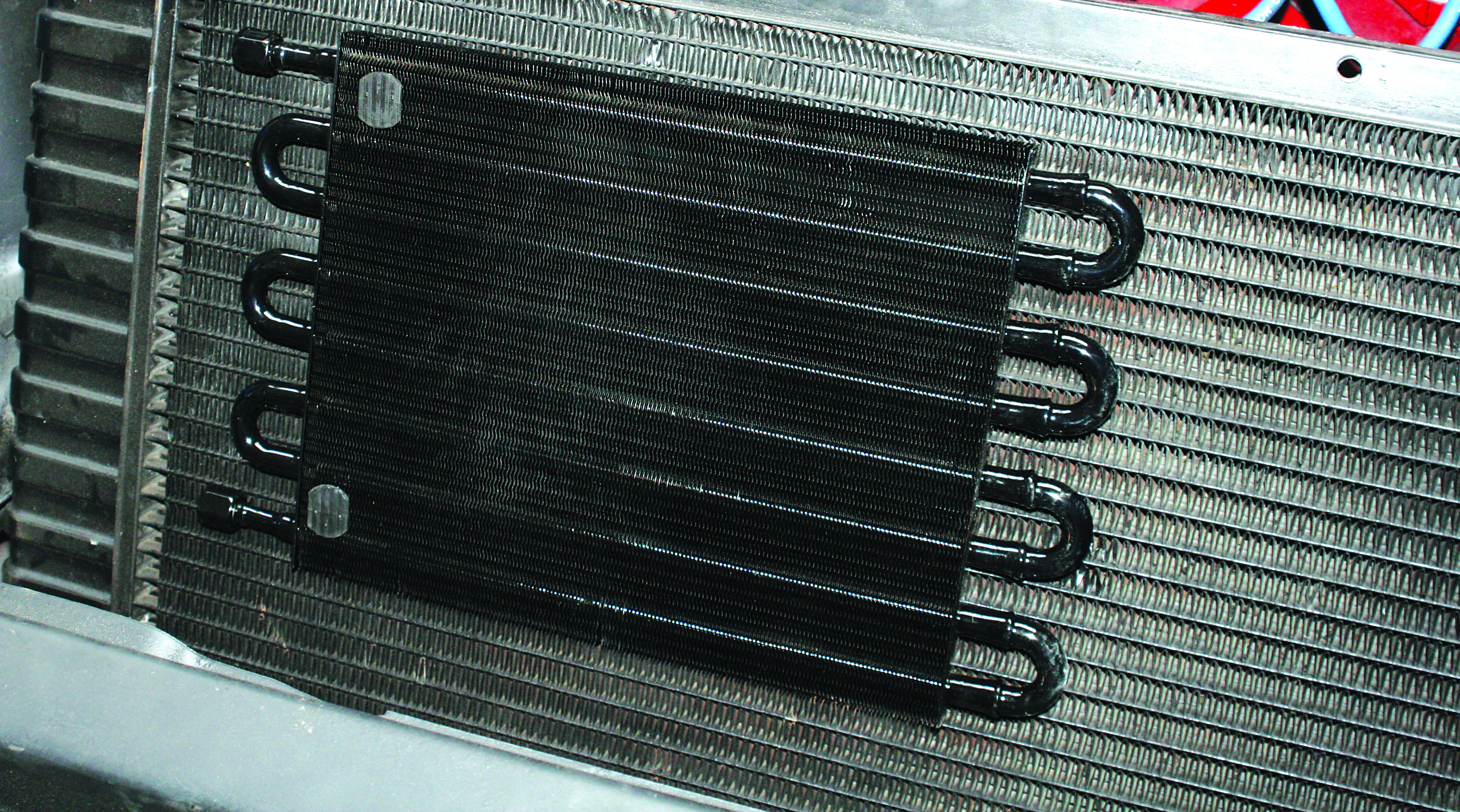

Do I Need An External Or Internal Transmission Cooler?

This is a common issue for gearheads, especially when swapping transmissions from manual to auto. All automatics need a cooler to maintain the 175-degree optimum running temperature. The best way to do this is to use an internal transmission cooler in the radiator. The reason for this is that transmissions do not like cold temperatures, ATF is much thicker at room temp than at 175, in fact AFT doesn’t thin out to the correct viscosity until it reaches 160 degrees, so if your transmission is running colder than 160, the fluid is putting more strain on the valves and seals. An internal cooler helps bring the ATF temp up faster so that your transmission is running at the optimum temperature.

External coolers are unregulated, so they will cool as much as possible, often taking the temps too low. If you are experiencing higher transmission temps or tow, then you may need both. An auxiliary cooler mounted after the internal cooler to reduce the fluid temps a bit more before they go into the transmission.

Why Not Run An External Transmission Cooler On The Radiator?

The main reason is that it increases the stack-up in front of the radiator, inhibiting the airflow through the core. Imagine a modified muscle car with AC (condenser in front), auto trans (cooler behind AC condenser) and then the radiator core, that is a substantial stack in front of the core. You can easily block 1/2-2/3rds of the core with these two alone, not to mention that the air that flows through the core is now much hotter than it would have been. Then let’s add an intercooler for boost, which goes in front of all of the rest, so you have a lot of mass reducing flow. Internal coolers are more efficient and reduce the overall stack-up, which is why they are recommended.

Do I Need A Radiator Cooling Fan?

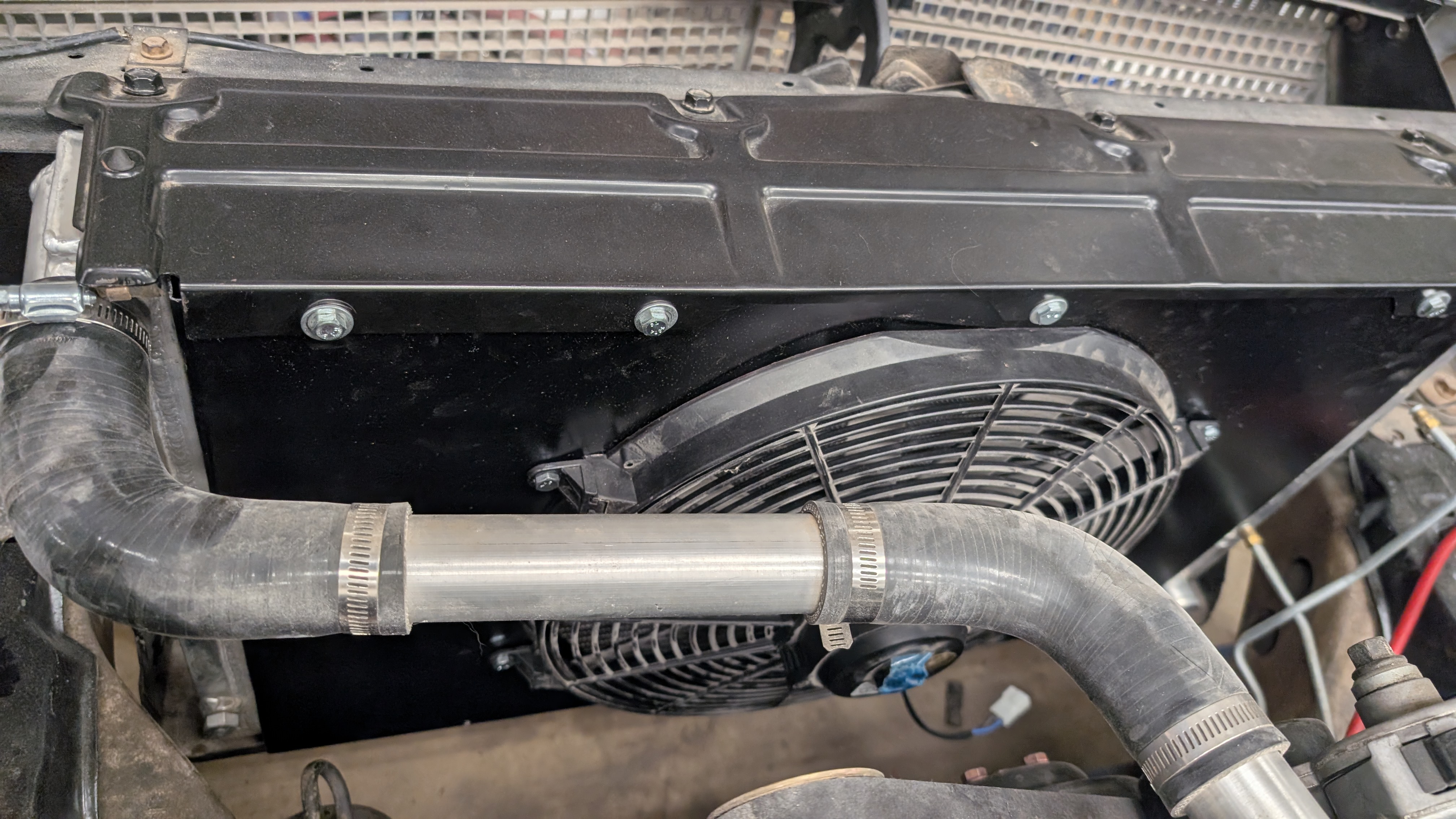

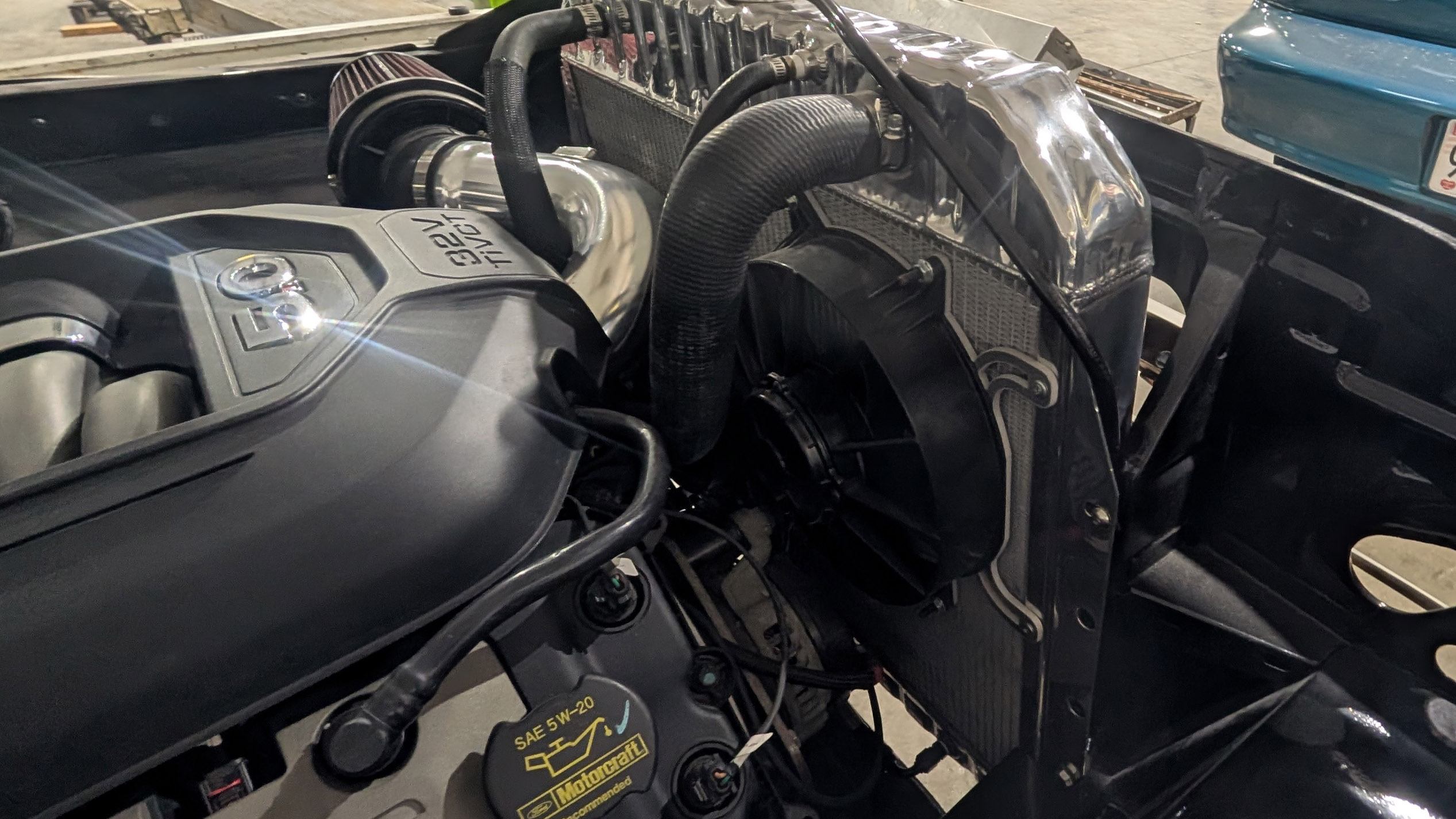

Moving beyond the radiator, the rest of the system is just as important. The biggest mistake many gearheads make with their cooling system is the fan. Mechanical fans are just fine, but they eat horsepower and are not controllable. Electric fans are the best option for any car that is not restrained by originality. Regardless of the fan style, all fans should be shrouded, especially mechanical fans. Without a shroud, a mechanical fan is just stirring up the air around it, there is little draw through the radiator at all. With a shroud, the fan generates a vacuum, pulling air into the radiator. This is only important below 40 mph, once the vehicle is moving 40 or faster, the natural airflow takes over.

Electric fans should be shrouded as well. The recommended distance between the fan and the radiator is 1-2”, with a full shroud covering the entire fan-side of the core. This forces the air through the entire core instead of just the area directly in front of the fan. It is very common to see electric fans mounted to a radiator with special zip ties, while this works, it will eventually rub a hole in the core. A shroud is far better, but a fan ring is the suitable solution for tight-fit vehicles where a shroud is less feasible. Fan rings mount to the perimeter of the radiator, eliminating the risk to the core.

Is There Really A Difference In Coolant Types?

There are many formulations for coolant as each manufacturer has their specific formulations, however in the United States, there are three main type of engine coolant: Original Green Inorganic Acid Technology (IAT), Organic Acid Technology or OAT-Based, and Hybrid OAT G-05 and G-11 coolants. You may ask “why does this matter to me, I have a 1970 Chevelle, the old green stuff is fine.” If you have the original engine, then sure, you would be right, but if you have LS swapped that Chevelle?

IAT (Classic Green) coolant is silicate-based ethylene-glycol. It is very good at what it does, but for a very limited time. IAT coolant is good for 2-3 years, after that it doesn’t work well too resist freezing and begins to eat the rubber in the hoses and seals. It is highly recommended than any engine using IAT coolant be flushed every other year with a chemical flush and then refilled with fresh coolant. Remember, IAT coolant is toxic to all living things, so dispose of it properly.

IAT coolant does not mix well with aluminum, over time the coolant will eat away at the aluminum, including the radiator, block, and heads. This is the main reason OAT coolants were developed. If you have an aluminum radiator, you should be running OAT or HOAT coolant.

OAT coolant goes by many brand names; one such name is Dexcool. While Dex was named the culprit by shade tree mechanics in a massive recall by GM in the 1990s, the actual issue was an incompatible plastic used for gaskets. The coolant melted the plastic over time, but Dex got the blame. GM still uses the exact same OAT coolant; the gaskets were changed. This stuff has longer life, up to 10 years, but we still recommend flushing it every 3-4 years, as OAT coolants do not like air, and will sludge up over time. This is the reason that all modern vehicles have fully sealed cooling system with no vents on the expansion tanks. OAT coolant does not like copper-brass, so if you have an older vehicle with a CB radiator, IAT is going to be the best choice.

The newest type of coolant is HOAT. Because IAT and OAT coolants can NEVER be mixed (they turn to sludge immediately), a hybrid coolant was developed, using a little of both technologies. Most OEMs use HOATs now (GM is the odd duck, sticking with Dexcool). With a solid 5-year lifespan, you can safely use HOAT coolant in place of either type for 5 full years. This is the “All-Makes” coolant you see at the store.

Tap Water Is Good Enough, Right?

NOPE. While just about every one of us has done it, filling your cooling system with tap water is a terrible option. The minerals in tap water create all kinds of havoc, including sludge, corrosion, crystalline formations, and some even become acidic when mixed with phosphates. Many import coolant formulations such as Honda and Toyota use heavier phosphates, hard water (high in calcium and magnesium) reacts very poorly with phosphates and can severely damage your engine over time. Tap water is also a major contributor to electrolysis in cooling systems. You should only use distilled water mixed 50/50 with the proper coolant. Better yet, you really should consider buying pre-mixed coolant, which ensures that you are getting all the good stuff and none of the bad stuff and you don’t have to mix it. Yes, You are “paying for water,” but it is the right water. Your Brita filter is not good enough; you need chemically pure water to avoid the contamination.

My Engine Is Running Hot, Can I Just Run A Cooler Thermostat?

This myth is one of the worst there is, as the thermostat does not have any control over the operating temperature of your engine. Your engine is going to run as hot as it is going to run based on the cooling system parameters. A properly designed system will maintain the temperature in a safe range. The only thing the thermostat does is open and close at a specific temperature, it is actually regulating the minimum temperature, not the top end. A 160-degree Tstat begins to open around 135-140 degrees and is fully open at 160. When the temps fall below 160, the Tstat begins to close until the temps rise again. If you have too high of a tstat, your engine will get up to temp faster, but you are closing off some of your cooling range, going to a cooler temp unit will only open the flow faster.

There are reasons to run a higher or lower thermostat, such as you want to be able to use the heater sooner from a cold start, or your engine needs to get up to a higher temp faster. Most modern engine ECMs don’t even turn the fans on until the engine is at 205-degrees, so going from 190 to a 170 tstat won’t do a thing to reduce the operating temperature unless the previous tstat was higher than the cooling system’s efficiency.

AS you can see, there is a lot more to cooling systems than just the raw parts, every piece of the puzzle needs to be compatible, from the radiator to the coolant and water you use. This article is a “5,000-foot view” of engine cooling systems. You can learn more on each of the above sections by clicking the links in the text above for each section. Gearheads spend the most money on their engines, why would you put it at risk by running the original 6-cylinder radiator and tap water?

The post Everything You Need to Know About Automotive Cooling Systems appeared first on The Online Automotive Marketplace.