The E31 BMW 8 Series was BMW’s first foray into the full luxury grand-touring car world in the modern era. The original 8 Series project began in July 1981 and was expensive, costing more than 1.5 billion deutsche marks. The project was completed in 1986, but the launch of the 8 Series was delayed due to the still-strong sales of the 6 Series coupe, which the 8 Series – offering more performance, more technology, and a substantially higher price – was created to replace.

Today’s AutoHunter Spotlight is one of these BMW super coupes, a 1996 BMW 850ci with 109,000 original miles, listed by a dealer in Denver, Colorado. (While that mileage may sound high, many of these cars have been driven past 200,000 miles and are still going strong.) The auction ends Wednesday, February 4, 2026, at 11:30 a.m. (MST).

The 8 Series was finally introduced to the public at the 1989 Frankfurt Motor Show, and the car was well received. Timing can be everything, though. The BMW 8 Series went on sale during the recession of the 1990s, when the appetite for high-end European cars was anything but at its peak. As a result, BMW sold a mere 6,920 units in the American market.

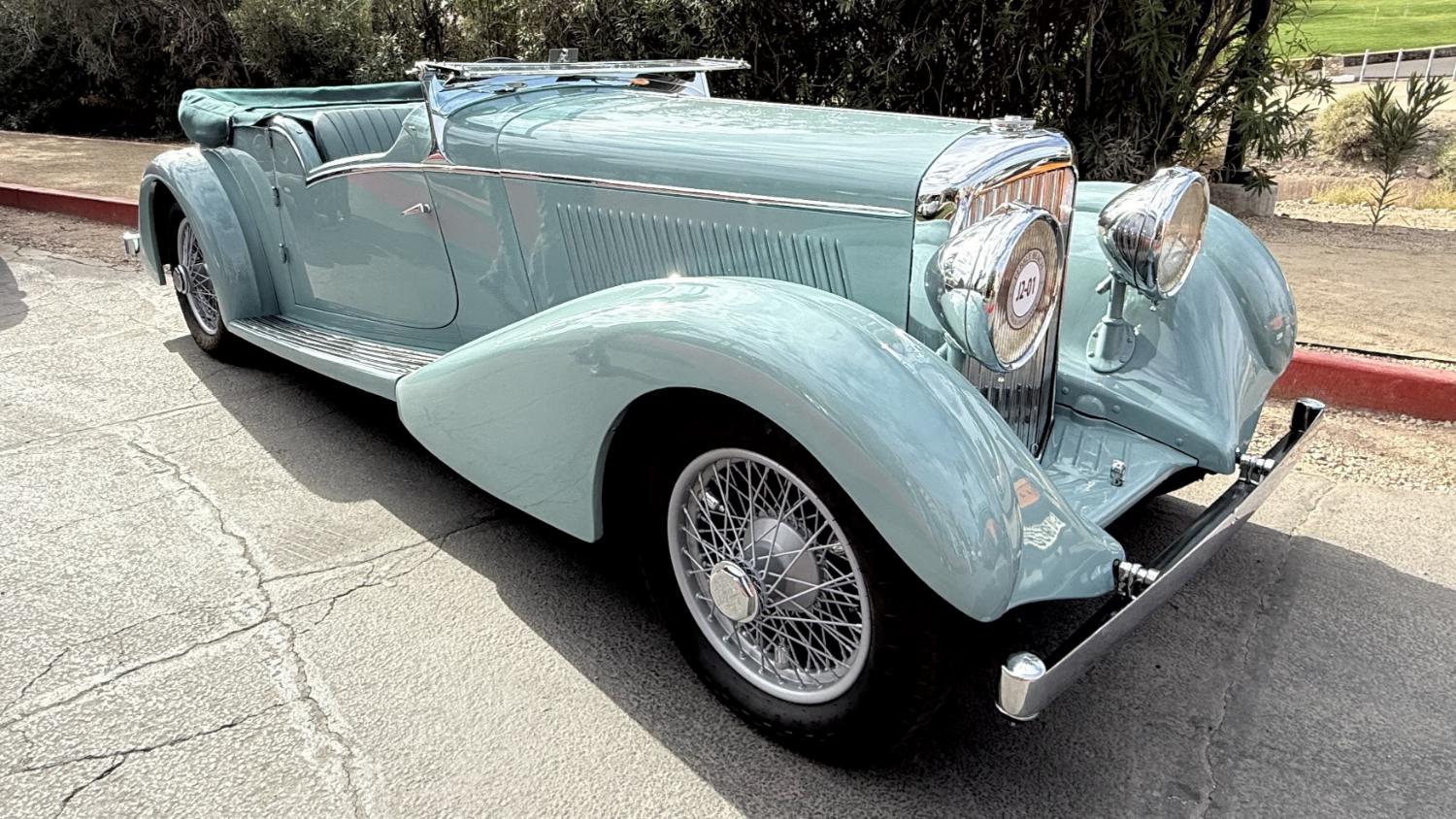

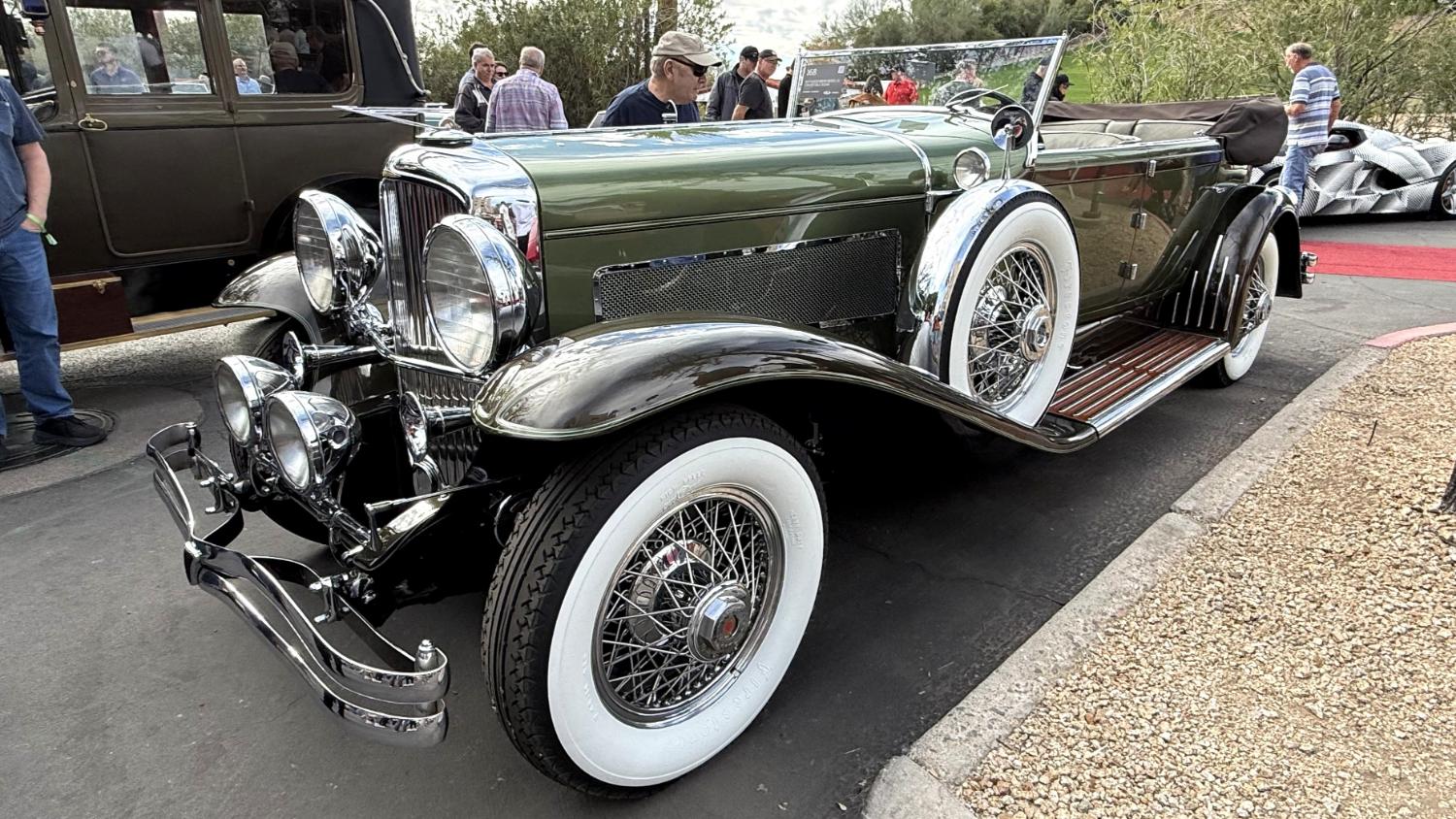

The seller describes this 850ci as being powered by its original M73B54 5.4-liter V12 mated to a five-speed Getrag ZF 5HP30 Steptronic automatic transmission. The car is finished in the great color combination of Oxford Green over a tan leather interior. It is offered by the selling dealer with an AutoCheck report and a clear title.

The exterior of this 850ci looks to be in overall good shape, with some small scratches visible. The AutoCheck report indicates the car had an incident resulting in what they call “severe structural damage” in December 2025, but I honestly don’t see evidence of that in the photos. That being said, I would want to have the car inspected by a BMW shop.

The interior looks nice. There is some minor wear on the seats, but otherwise everything appears to be in good overall condition. The seller notes that there is some cracking on the center console bezel.

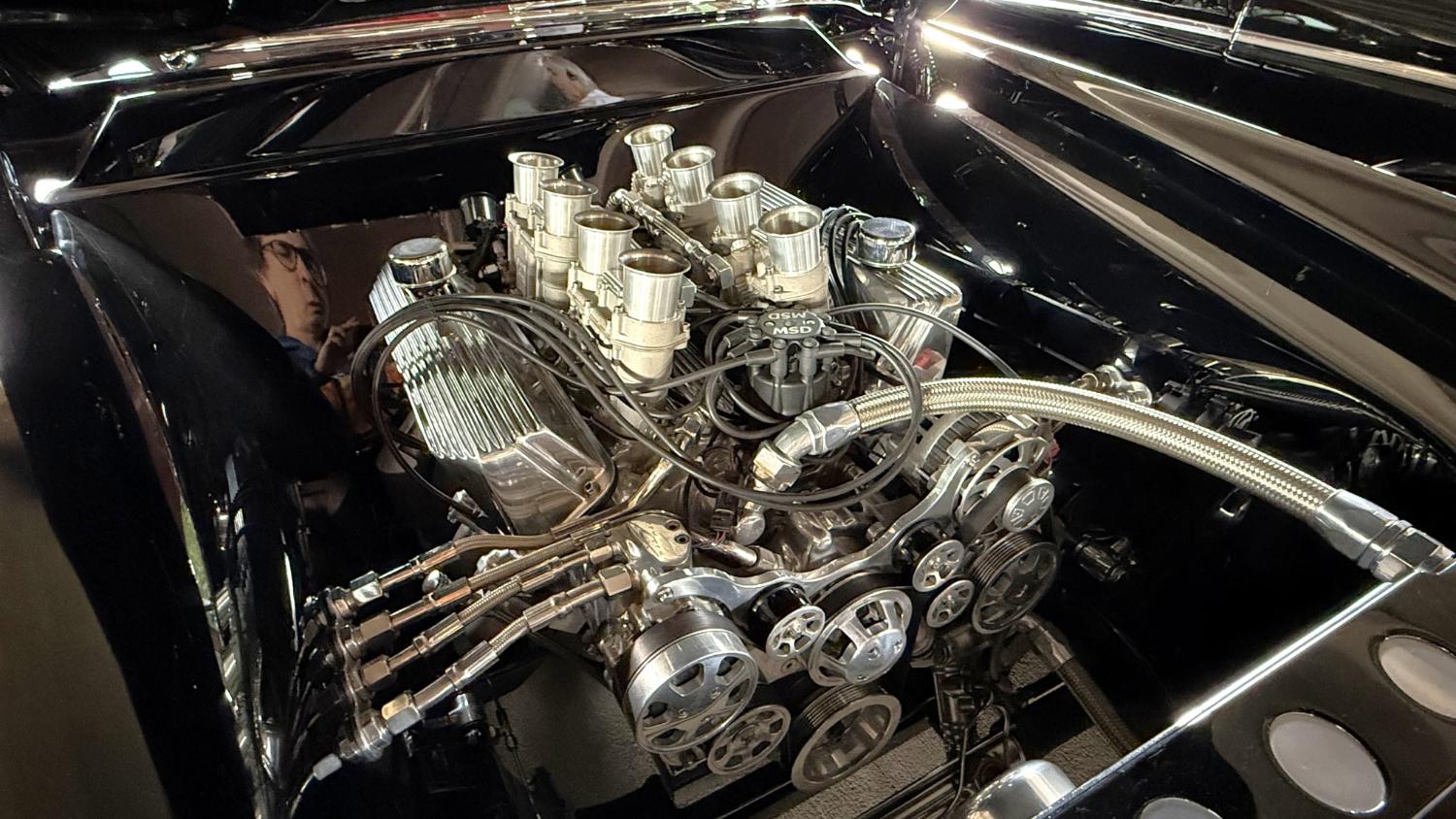

Under the hood is the awesome BMW M73B54 5.4-liter SOHC V12, which produces 326 horsepower and 361 lb-ft of torque. When it debuted, the model was said to be capable of a 0-60 time of 6.3 seconds and a top speed of 156 mph. The engine compartment looks to be nice and clean, and the seller states that the car was serviced last year.

As mentioned earlier, I would advise getting a few more details about this car from the seller because of some of its history. This can easily be asked about in the comments section of the listing, and I am sure that the seller would respond. If it checks out, then I would throw a few bids on this car, because a V12-powered BMW GT car is something very special. Has any of this piqued your interest? If so, don’t delay – the auction for this 1996 BMW 850ci ends Wednesday, February 4, 2026, at 11:30 a.m. (MST).

Visit the AutoHunter listing for more information and a photo gallery